Printable Version of Topic

Click here to view this topic in its original format

914World.com _ 914World Garage _ Mueller's 1st How-To Series :) (Type IV)

Posted by: Mueller Feb 19 2003, 01:05 PM

Some people have been asking how to remove and or plug up the air injection ports on '75 and '76 2.0 motors.

A few different methods can be done:

1)Welding of the holes, this is only practical if you know you will never need the air injection holes again. It is also only practical if you have the heads already removed from the motor.

2)Threading in a 10mm valve adjusting screw or allen head screw. I don't like this route since there is a good chance of the screw becoming loose down the road. (Jon Watts just had this happen not too long ago)

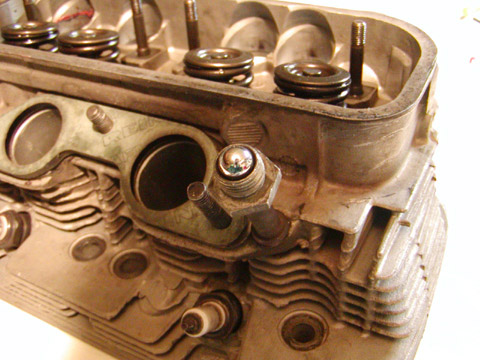

3)Using a bolt to plug the hole...this is shown in the first picture. The advantage of this route is that you can use the bolt to secure the sheetmetal to the motor and you can remove the bolt in the future if need be in case you must once again have the air injection ports fuctional.

I have had the bolts work themselves loose...so I made a little bracket which uses the intake stud to make sure it cannot come loose.

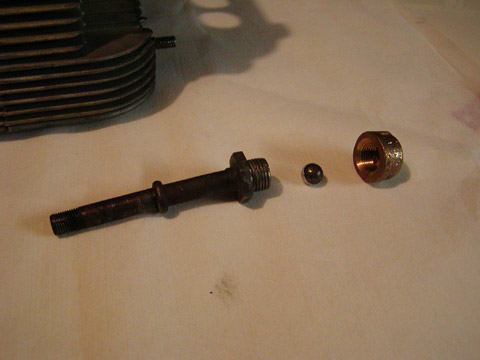

4)Keep the air injector in the head and plug the top of the injector.The last few pictures show this. I used a ball bearing to get a better seal, this acts just like the valves in the head to create a better seal. The cap is from the local hardware store...I believe it is for a 1/4" pipe

Like #3, this can be benificial in the future since it can be taken apart and easily put back into service.

I welcome other ideas so that we can expand the knowledge ![]()

Disclaimer: Disconnecting smog equipment might be illegal in your area, check local and state laws first....... ![]()

Posted by: jonwatts Feb 19 2003, 01:40 PM

Cram a banana in the hole. It won't plug it but it makes a good banana launcher.

Posted by: RustyWa Feb 19 2003, 02:43 PM

Thanks again for the pics Mike.

Question about the bolts. Are they just a fine thread metric bolt?

Also, do the tips of the injector stick into the exhaust port? I want to use the old injectors to get the correct length bolt...but I don't want them to stick in to the exhaust stream. By the way, engine is still in the car and exhaust is still bolted up to the heads.

If Performance Products will finally do there 20% off sale, again, I'll be able to buy my new Dansk OEM muffler and verify the length while I'm backdating my exhaust.

Posted by: Mueller Feb 19 2003, 03:06 PM

The bolts I used I think are M10's with a 1.25 pitch

(I'll have to verify this tonight)

The tips do not protrude into the exhaust port, it looks like you can go another 3mm-6mm longer with the bolt before you started to distrupt flow.

Call Performance and ask for a better price...the worst to happen is for them to laugh ![]()

Jon,

"I'm not falling for the banana in the tailpipe trick again" ![]()

Posted by: GWN7 Feb 19 2003, 06:00 PM

Did you use Loctight on the treads? I know it comes in various grades, from easy to never come out.

Posted by: Curvie Roadlover Feb 19 2003, 07:37 PM

This is a topic near and dear to my heart. I've been asking peoples' opinions about this for a while now. I even brought it up last Saturday at our "tech session" at Munk Motors here in MI. There are 2 objectives: #1, plug the hole preventing exhaust from coming into the engine compartment; and, B, prevent whatever you use from backing out. Most people I've talked to agree that no type of loctight will hold up to the extremes in temp. there. For sealing the threads, the mechanic at Munks recommended using a product called Nissan PBC Grease - available at Nissan dealers. He says it will hold up (seal) forever regardless of temperatures. It's a bit pricey, though, at $30.00 for 16 oz. ![]() As far as preventing the plugs from backing out, I like your idea about building a bracket off the intake studs. On my car I currently have bolts in the holes with loctight

As far as preventing the plugs from backing out, I like your idea about building a bracket off the intake studs. On my car I currently have bolts in the holes with loctight ![]() and I've painted one corner of each bolt head to be able to see if they're loosening, but I don't want to have to constantly check the bolts and worry if they're coming loose. I plugged my injector holes in Nov. when I got the car back from CA and I haven't driven it since so as to check for exhaust leaks or bolt loosening but I'm not real happy about my set-up. I also like the ballbearing/pipe end method and may switch to that. I'm anxious to here what others have to say about this topic.

and I've painted one corner of each bolt head to be able to see if they're loosening, but I don't want to have to constantly check the bolts and worry if they're coming loose. I plugged my injector holes in Nov. when I got the car back from CA and I haven't driven it since so as to check for exhaust leaks or bolt loosening but I'm not real happy about my set-up. I also like the ballbearing/pipe end method and may switch to that. I'm anxious to here what others have to say about this topic.

Posted by: Curvie Roadlover Feb 19 2003, 07:45 PM

I just went out to take a look at the car and realised that the intake studs aren't long enough to accomodate a bracket like Muellers. I was also thinking about drilling holes in the bolt heads and using safety wire but that would be a bitch to do and it would look cheesey. The ballbearing/pipe end fix is looking better all the time.

Posted by: Mueller Feb 19 2003, 11:29 PM

I just measured the air injection tube....the threads are 10mm with a 1.0 pitch.......

A bolt 50mm long will be perfect.

Tom, instead of making a bracket to capture the top of the bolt, make a washer that will fold up around the side of the bolt on two sides....make it so that part of the washer will rest up against the gasket...this will prevent the bolt from turning...you'll have to unbend the tabs on the washer to remove the bolt.

Posted by: Brad Roberts Feb 19 2003, 11:31 PM

Mueller,

Check the threads at the top of the air tube. I personally dont beleive that they are standard threads. You may have "forced" a pipe thread setup on there, but I have always used 944 fuel rail caps (they are metric).

B

Posted by: Mueller Feb 19 2003, 11:33 PM

No forcing at all......these caps spun on like they had been made for this application....hey, what time are you going to be at the shop in the morning??

Posted by: Brad Roberts Feb 19 2003, 11:35 PM

I get there at 8am on most days. I'm home early this evening..so I should be on time. Al is there at 8am.

I spent a lot of time at OSH with them in hand and never found anything that fit correctly. The rumor I was told: They didnt want anybody "capping" them easily.

B

Posted by: Mueller Feb 19 2003, 11:39 PM

One of the reasons for the ball bearing was to insure a good seal...I'll bring an extra set I have for you to check out, not that you do this kind of thing on a regualr basis...

Posted by: Brad Roberts Feb 19 2003, 11:44 PM

Soon.. my "regular thing" will be production of stainless products and 1 or 2 6 conversions or 6 swaps.

Not much interested in 4cyl cars (injection is another subject) Lengthy talks about getting the dyno running again are paving the way.

B

Posted by: kdfoust Feb 19 2003, 11:55 PM

If Performance Products will finally do there 20% off sale, again, I'll be able to buy my new Dansk OEM muffler and verify the length while I'm backdating my exhaust.

If you're a PCA member Performance will give you 25% off all the time.

Posted by: Mueller Feb 20 2003, 12:08 AM

thanks for the tip kevin...that is something that needs to be added to the vendor list

Posted by: seanery Feb 20 2003, 08:05 AM

actually, the PCA discount at Perf Prod number changes. I've had several different amounts 15% - 25% depending on the item. I used to go in about once every 2 weeks or so.

You also have to ASK for the discount.

Posted by: mr914 Feb 21 2003, 10:59 AM

I drilled the head of my bolt with a .064 drill bit and ran safety wire thru it.

Posted by: Jeffs9146 Feb 21 2003, 11:44 AM

[QUOTE]Most people I've talked to agree that no type of loctight will hold up to the extremes in temp.

JB Weld!!!

LOL

Jeff

Posted by: Curvie Roadlover Feb 22 2003, 06:16 AM

OK, with the help of SMOG's BS Chairman, I've come up with the plan that I'm going to use, based on many suggestions from many people. To plug the holes I'm going to use Allen head bolts. There are 2 reasons: First, wrench access is very tight there, especially because of the close proximity to the manifold flange, and getting an allen wrench in there will be a piece of cake. Second, an allen bolt will be the easiest to drill for safety wire as you only have to drill from the outside of the head to the hole for the wrench. To seal the threads, I'm going to use anti-seize, as this will certainly hold up to the temperatures there (thanks, Bob "I know what I'm talking about" Freeman). Loctight's 400 degrees F isn't enough. I'm sure the temps get higher than that there. I'm also going to use a lock washer for added protection to keep the bolt from backing out. I've spent alot of time thinking about this issue and sought alot of people's advice on this and I think this is the best solution for me. HTH

Posted by: Bleyseng Feb 22 2003, 10:07 AM

Eric, Lowe's still might carry them. Hardwick's in the U-District has tons of oddball bolts, and there is TacomaScrew which should have them. Oh, yeah, try McLendons in Renton closer to your house.

Geoff :flower: ![]()

Posted by: RustyWa Feb 23 2003, 11:55 AM

Curvie, good idea on the anti-seize. Wish I thunk of that. I tend to over think things sometimes.

Geoff, I'll try Tacoma Screw...again....but talk with someone who gives a shit......long story. I think they have them in the M10x1.0 50mm. Lowes didn't have them in the correct 1.0 thread pitch. That's a bugger pitch.

Posted by: RustyWa Feb 25 2003, 06:00 PM

Well I struck out at Tacoma Screw. Another local place had them in 70mm length that I could cut down, but they were VERY expensive!! $7.23 each. It's starting to look like a hex head bolt..... ![]()

Curvie, let me know if you find them in the socket head (allen) style.

Posted by: seanery Feb 25 2003, 06:21 PM

Rusty,

Make friends with someone in Santa Monica, they have a killer little hardware store I can't remember the name but they are next to a Nissan dealer.

This place has everything metric & sae even in stainless.

I used to go there for funky stuff for my boat (that I lived on) and for the motor mount in my -6 conversion.

I'd go for ya, but I'm a little too far east now.

Posted by: Curvie Roadlover Feb 25 2003, 06:32 PM

Eric,

On saturday I'm going to a local hardware store by my house. They specialize in rare hard to find fasteners. I used to go there when I raced karts and I was almost always able to get what I was looking for. And I was sometimes looking for stuff far more rare, i'm sure, than metric allen head bolts. If they have 'em I'll buy as many sets of 4 that I can and let you know either way. Once they didn't have what I was looking for. I asked the guy where to go to get what I wanted. He said, "If we don't have 'em, you can't get 'em"

Posted by: Dave_Darling Feb 25 2003, 08:06 PM

For metric fasteners, check with your local Caterpillar Tractor dealer. I am told they are one of the largest users of metric fasteners in the world.

--DD

Posted by: RustyWa Feb 26 2003, 02:38 PM

Curvie, yes keep me updated on what you find this weekend. If you find the allen heads in the 50mm length and they are not to expensive, let me know.

Posted by: Curvie Roadlover Feb 27 2003, 04:52 PM

OK I got the fasteners (almost). They're 10mm 1.0 pitch socket cap (allen wrench) bolts of 50 mm length. The hardware store didn't have 'em in stock but could get them for me. I had them order 16 for me so I can plug my injector holes and supply 3 other cars with them. They are costing me $1.40 ea. I could probably send them to you for about $10.00 total or less depending on how much it costs to ship them to you. Anyone interested let me know. RustyWa, I'll hold a set for you.

Hey I'm now in the triple digits in posts here. ![]()

Posted by: RustyWa Feb 27 2003, 05:16 PM

Great! How long until they arrive? That is a good price.

Posted by: Curvie Roadlover Feb 27 2003, 06:58 PM

I suspect a few days. I'll let you know as soon as I get them.

Posted by: Curvie Roadlover Mar 10 2003, 11:57 AM

I still hadn't heard from the hardware store so I called today. They said they had no record of my order for the bolts (perhaps they're affiliated with a company in Marrieta, GA). Anyways I ordered them again. Now they're $3.28 a piece. The $1.40 was for hex head bolts, apparently. Because of the higher price, I only ordered 12. Enough for my car and 2 others if anyone is interested. I'll save a set for you, RustyWA, if you still want 'em. I'll let you know when I get 'em.

Posted by: RustyWa Mar 10 2003, 01:47 PM

I almost sent you an e-mail yesterday asking about an update... Yea I will still take a set. Just let me know when you get them and verify that they are the correct length and pitch. I'll send you some $$ by check or Paypal, whichever you prefer.

Thanks.

Posted by: seanery Mar 11 2003, 09:46 AM

Hey guys,

If this fails to come through let me know. I have a buddy in the Fastener industry. They usually do commercial sales, but who knows.

We're playing cards together on the 28th, so I'll ask him then.

Posted by: Lawrence914-6 Mar 11 2003, 01:02 PM

Hey Mike,

On my 76 2.0, I was concerned that I would damage the threads if I pulled the smog tubes. I ended up just getting some nice brass caps at my local FLAPS. Those, and a bit of teflon tape, and they were very, very snug and air tight.

-Rusty ![]()

Posted by: Curvie Roadlover Mar 12 2003, 07:40 PM

I got 'em!!! I got enough for my car and RustyWa plus 4 more bolts - enough for 1 other car. Let me know if you're interested.

Posted by: Curvie Roadlover Mar 12 2003, 07:41 PM

A comparison

Posted by: RustyWa Mar 12 2003, 10:01 PM

Those should really work well and look good to boot! I'll get your check ready for tomorrow.

Thanks again.

Posted by: RustyWa Apr 1 2003, 12:03 AM

Here are the socket head bolts installed. As you can see in the photo, there is not much room between the bolt head and the gasket.

Thanks Curvie!

Posted by: RustyWa Apr 1 2003, 12:05 AM

Closer view...

Posted by: Curvie Roadlover Apr 1 2003, 05:41 AM

Very Nice! ![]()

Posted by: Curvie Roadlover Apr 1 2003, 05:43 AM

I still have 4 of those socket cap bolts left (enough for 1 more car), if anyone is interested.

Posted by: Mueller Jul 12 2005, 11:30 AM

Tom,

So how have those bolt's held up to the task at hand?

What did you use to help minimize the bolts backing out?

Posted by: Britain Smith Jul 12 2005, 12:21 PM

Jeez, this is an old thread. Man...Mueller, you must have been bored to dig this one up.

-Britain

Posted by: fatlando Jul 12 2005, 12:35 PM

Thanx fellas,

This site rocks! I'm having the same problem in my "missing bolt" thread. As usual, 914club is the shit!

fat lando

Posted by: Brian Mifsud Jul 12 2005, 12:42 PM

Hey! I recognize those pipe caps and ball bearings!!

(I bought Mueller's engine......)

All seemed tight when I pulled them off. The bronze/brass caps are a nice touch because they won't seize on the steel, no matter how long they are left. The ball bearings surprised me when they dropped out....

anyhow, I discovered my "1976" 914 was actually built in 10/75, so I believe I can file for a smog exemption....

Posted by: Tom Perso Jul 12 2005, 02:31 PM

Huh...

This EXACT problem ruined me from driving my lovely new bride away from the church at our wedding.

I have 1.8L Bus heads on my 2270. I had the air injection holes welded up when I had them ported. Seemed like a good idea to me.

Apparently, one of the welds wasnt' that good. The morning of the wedding day, I went to fire the car up and the first time it caught I heard a loud boom and then "Bam bam bam bam" on one cylinder. I thought for sure I had overheated the motor on the drive up to my future in-laws and it stretched the studs... Once it cooled there was no more seal.

So, I had to use my parents Acura TL. Boohoo.

After the honeymoon, I pulled the motor and tore it down - found the problem but never found the weld bugger.

I just threaded a 10x1.0x50 bolt into it and called it a day. Car hasn't run since. Bastard.

Tom

Posted by: maf914 Jul 13 2005, 12:27 PM

| QUOTE (Brian Mifsud @ Jul 12 2005, 10:42 AM) |

| anyhow, I discovered my "1976" 914 was actually built in 10/75, so I believe I can file for a smog exemption.... |

Brian,

Hate to rain on your parade, but I think this came up in an earlier thread and the end result is you're stuck with the '76 designation. Maybe my memory is wrong and someone else can clarify. There is a thread somewhere in the archives.

BTW, I had a set of air injection nozzles brazed shut and used them to plug the exhaust ports with no problem.

Posted by: lapuwali Jul 13 2005, 01:03 PM

100% of the "1976" 914s were made in 1975. They were just selling leftover inventory. The '76 smog rules were the same as the '75 (NOT the same as '74), so it worked for them at the time. Unfortunately, it really hurts '76 914 and 912E owners in California, though.

Generally speaking, the year on the title is the ONLY thing the DMV looks at or cares about. It may be possible to convince them it's really a '75, and get the title changed. I've heard of this being done (I once had a '74 Alfa that had been re-titled as a '73, back when '73 and older cars were smog exempt, but '74 still required it), but I have no idea what the procedure is, or who's palms you'd have to grease to make it happen.

Powered by Invision Power Board (http://www.invisionboard.com)

© Invision Power Services (http://www.invisionpower.com)