MattR

Jun 5 2005, 02:58 PM

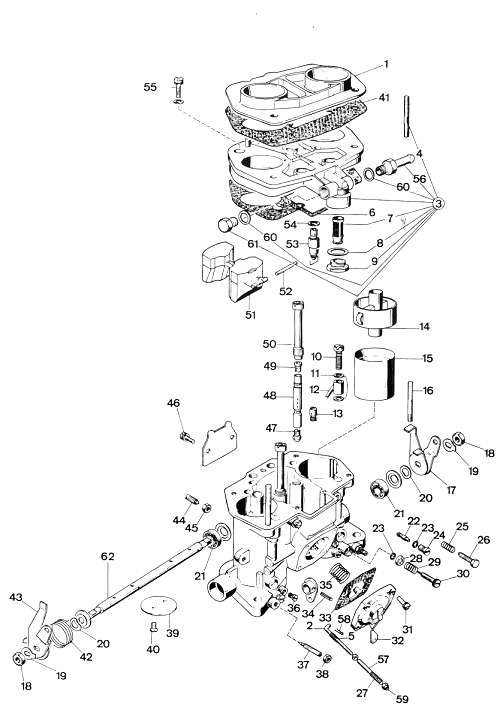

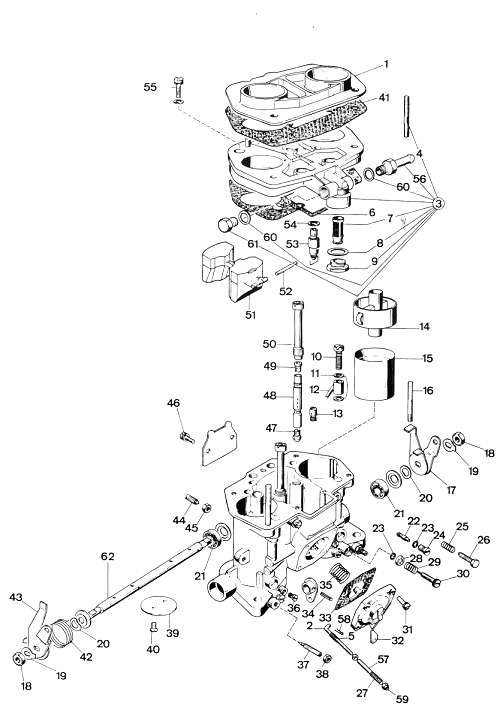

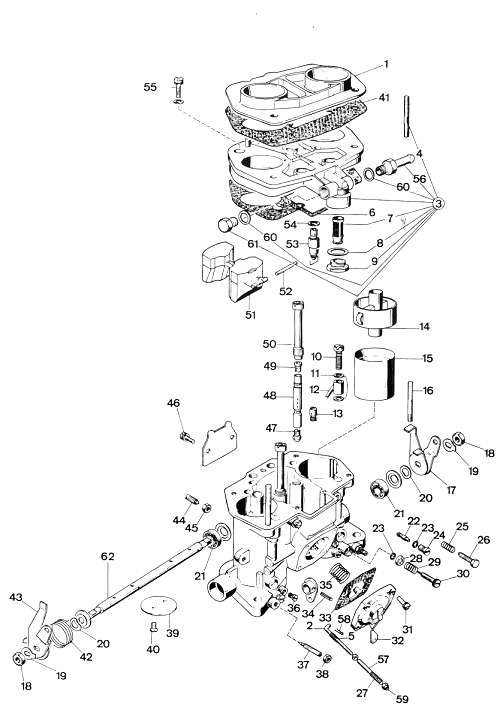

This weekend I rebuilt my carbs using a Redline carb rebuild kit. Everything went without a hitch, except I was a bit confused on number 53 (see pic)

The pieces I pulled out were marked "175" and the rebuild kit had "200". What does this stamping mean? Which should I use? The 175s looked pretty hosed, but if I have to I'll buy new "175"s.

This is going on a 2056 with 40s used as a driver.

ArtechnikA

Jun 5 2005, 03:59 PM

air correction jet.

since carburetors meter fuel (approximately) proportional to airflow, they have a tendency to get richer and richer the more air they flow - i.e. - high-speed, high-load.

that tendency is (mostly) balanced by using an air bleed to decrease the metering signal at high airflow. like all Webers, the size is the diameter of the hole in hundredths of one mm - e.g. 200 is 0,200mm. since flow is (approximately) proportional to the area of the hole, a relatively small diameter change can have a larger area, and therefore flow, change.

so - a bigger air correction means the engine will run a little leaner at high load than a smaller air correction. it's kind of an "anti-main-jet." complicated by the effects of the emulsion tube, which is a bit of a black art and intended to improve the transition from lower flow to full throttle.

bigger air correction should improve your highway cruise fuel economy. but if you see any symptoms of excessive leanness, go back to your 175's.

MattR

Jun 5 2005, 04:07 PM

Okay, it looks like Im a bit confused. Lets do a run down of jets:

47- main jet

49- ???

53- air correction jet (?)

22- idle jet

12- accelerator pump jet

48- emulsion tube

13- ???

(the numbers correspond to the numbers in the picture)

ArtechnikA

Jun 5 2005, 04:21 PM

| QUOTE (MattR @ Jun 5 2005, 06:07 PM) |

Okay, it looks like Im a bit confused. Lets do a run down of jets:

47- main jet

49- ???

53- air correction jet (?)

22- idle jet

12- accelerator pump jet

48- emulsion tube

(the numbers correspond to the numbers in the picture) |

okay - i'm confused too. disregard what i said about #53 being the air correction... it's not. #49 is. (air correction/emulsion/main is the standard stack.) i'll stand by what an air correction does, but #53 isn't one...

i can't quite see where that part fits in, and it doesn't seem to be referenced in my Webr tuning reference. where's it go, again ?

{edited to correct number of AC jet - again...}

MattR

Jun 5 2005, 04:47 PM

Its a two piece part. The top half screws into the top plate of the carb with a 12mm hex (iirc) and has a crush washer included in the rebuild kit. The bottom half is a tapered pin with a wire oin the bottom half that attaches to the float.

I think in the blue haynes weber repair manual they refered to it as a "needle valve" or something. I dont remember and I dont have the book with me.

Tom Perso

Jun 5 2005, 04:55 PM

I think that is just a valve to cut off fuel flow when the float comes in the bowl. I thought it was just an "on/off" kind of switch - the float level is the important part.

I'd say go with the new one and check your float level again...

Tom

skline

Jun 5 2005, 04:55 PM

The needle valve is what the float moves up and down to meter the amount of fuel coming in, if it is not set correctly, your bowls will over flow into the carb.

Eidt: The 200 will work just fine.

ArtechnikA

Jun 5 2005, 04:56 PM

okay - i was gonna say needle valve...

i wouldn't worry about a number, then. i don't recall ever seeing a number on a needle valve, or reading that they came in different calibrations.

i would use all the same of whatever you use, tho...

MattR

Jun 5 2005, 05:03 PM

got it, thanks guys

ChrisFoley

Jun 5 2005, 09:27 PM

You may not experience any issues with using the 200 but the chart in my Weber book suggests using a 150 for engines up to 60 hp max per carb and a 175 up to 110 hp per carb. The 200 is rated for up to 150 hp per carb.

The needle valve controls the rate at which fuel is allowed into the float bowl. Too large a needle valve can cause hysteresis (instability) in the fuel level in the bowl which may cause uneven running, ie. worse gas mileage.

MattR

Jun 5 2005, 10:10 PM

Well i'll be around the 110 mark, maybe a little above, so I guess 200 should be playing it safe?

ChrisFoley

Jun 6 2005, 05:45 AM

| QUOTE (MattR @ Jun 6 2005, 12:10 AM) |

| Well i'll be around the 110 mark, maybe a little above, so I guess 200 should be playing it safe? |

You're looking at total hp.

The numbers I posted are per carb.

A pair of IDFs with 200 needle valves are good from 220 to 300 hp according to the book.

I would suggest putting the 175 seats back in, but using the new needles. They should fit together just fine, and the part that wears the worst is the needle.

MattR

Jun 6 2005, 12:07 PM

Hmm, I just did a check on CB and they only have 200, 250, and 300.

http://www.cbperformance.com/catalog.asp?ProductID=568

Joe Ricard

Jun 6 2005, 12:17 PM

I just love it when someone goes off the deep end offering info. I had to go back 3 or 4 times to look at #53. Knowing it wasn't the air correction but Needle valve for the float bowl level.

Then thought maybe he got the number wrong and meant air correction.

After a few more posts I thought my head was going to explode.

Racer Chris has the right answers.

SO when are you putting the carbs back on the car? I think some of us can help there too.

MattR

Jun 6 2005, 12:22 PM

Okay, I'll just reuse the seats and replace the needles. Thanks!

Carbs on the car shouldnt be too bad. Ive done it a bunch of times on my 912. If I do run into a snag, I'll post away! The engine goes in next week when I get the car back from paint, then carbs go on.

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please

click here.