(someone said they heard of it being done with a 933 master cylinder and a Wilwood slave?)

Full Version: Hydraulic clutch for a 915 Wevo(Fixed it w/o $$$)

Has anyone converted to this from the cable/pulley system. Need to upgrade. Any help would be appreciated! Photo's too if you've got 'em.............

(someone said they heard of it being done with a 933 master cylinder and a Wilwood slave?)

(someone said they heard of it being done with a 933 master cylinder and a Wilwood slave?)

964 pedals have the necessary hydro clutch master. Wevo makes an annular TO bearing for the 901, and probably for the 915 as well. That'd be the simplest thing. You can also go with Tilton pedals and MCs, but that will require even more fabrication I think.

There are a number of ways you can work out the slave cylinder issues, but they all require fabrication. Flex is a real issue in many cases; there was a guy on the Bird's racing board a while back who wound up doing a lot of reinforcement to his slave cylinder mounting.

--DD

There are a number of ways you can work out the slave cylinder issues, but they all require fabrication. Flex is a real issue in many cases; there was a guy on the Bird's racing board a while back who wound up doing a lot of reinforcement to his slave cylinder mounting.

--DD

I think Rich Johnston has a set up...

You should have a look at this thread: http://www.914world.com/bbs2/index.php?sho...ydraulic+clutch

QUOTE

Wevo makes an annular TO bearing for the 901, and probably for the 915 as well.

It is true...just buy the Wevo TO bearing and be done. What a nice set up!

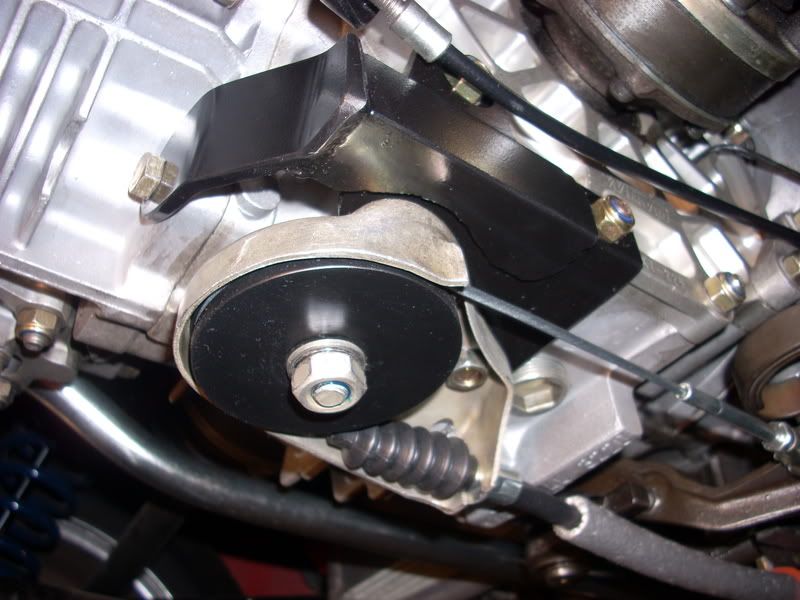

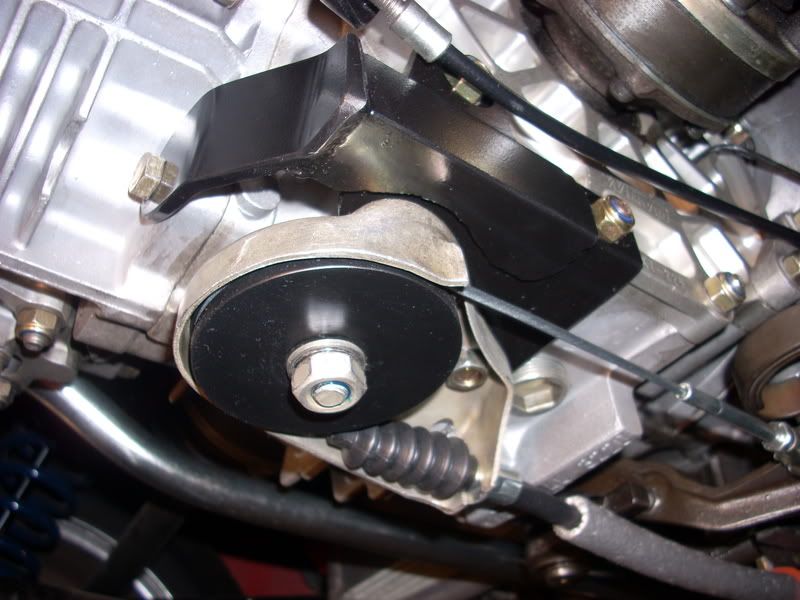

Fixed it without an expensive hydraulic clutch fabrication! Solution = remove the flex! First.....make a support bracket for the clutch pulley, and then 2) Make a clutch cable reinforcement plate for the firewall. Now, it feels tight and precise, without any flex or slop. Will try to add pic's!

where did you get that pulley? I want one!

From Patrick Motorsports.....He sells the pulley which should be enough for a standard clutch. I have a HD clutch which was causing flex at the pulley and at the firewall...hence the modifications. Good Luck

[url=http://www.patrickmotorsports.com/]

[url=http://www.patrickmotorsports.com/]

I never had an issue of mine flexing. I cut mine from a 3x3x3/8" angle iron.

Nice looking fab work!

I found that in my case with a heavy duty clutch the 914/6 cable is just too small in diameter to give smooth modulation. It worked perfectly fine but it just wasn't as smooth as I would like with small movement. The 911/915 cable is huge in comparison.

I installed a hydraulic clutch using CNC stuff for about 150.00. A new cable and a Patrick pulley is $100.00 so not a big difference in price. Fabrication is a few hours longer.

I think for the light weight pressure plates the cable is adequate. When going to a heavy duty 915 setup you might find the cable works fine but the hydraulic setup (while requiring about the same pedal pressure) is significantly smoother than the cable and more pleasurable to drive on the street. Just my opinion though.

I found that in my case with a heavy duty clutch the 914/6 cable is just too small in diameter to give smooth modulation. It worked perfectly fine but it just wasn't as smooth as I would like with small movement. The 911/915 cable is huge in comparison.

I installed a hydraulic clutch using CNC stuff for about 150.00. A new cable and a Patrick pulley is $100.00 so not a big difference in price. Fabrication is a few hours longer.

I think for the light weight pressure plates the cable is adequate. When going to a heavy duty 915 setup you might find the cable works fine but the hydraulic setup (while requiring about the same pedal pressure) is significantly smoother than the cable and more pleasurable to drive on the street. Just my opinion though.

I think for the light weight pressure plates the cable is adequate. When going to a heavy duty 915 setup you might find the cable works fine but the hydraulic setup (while requiring about the same pedal pressure) is significantly smoother than the cable and more pleasurable to drive on the street. Just my opinion though.

Mine operates smoothly with the 914/4 cable. Not sure what you mean. We are using a heavy duty pressure plate and haven't noticed anything unusual. It drives much like a stock clutch (just a little more pedal pressure).

Of course, this is not a street car either so I don't have any street miles on it and don't know how it would feel in traffic, but it's fine when driving through the paddock.

John, mine worked fine too with a cable. It just lacked the smoothness needed for my clutch. My disk is a special Kennedy unit I had made with a marcell (sp?)spring only on the PP side and none on the flywheel side. This makes for a very quick disengagement since the disk does not need to slide on the tranny splines to move away from the flyweel. I feel this is one of the main reasons my tranny shifts so well.

In my case the disk also makes for a rapid engagement since it does not have to compress the marcell spring. Not like a race disk but faster than a stock disk. Small movements made a huge difference during engagement. The hydraulic system makes it all smooth as silk.

Disk picture: Mine on the right and stock on the left

Click to view attachment

In my case the disk also makes for a rapid engagement since it does not have to compress the marcell spring. Not like a race disk but faster than a stock disk. Small movements made a huge difference during engagement. The hydraulic system makes it all smooth as silk.

Disk picture: Mine on the right and stock on the left

Click to view attachment

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please click here.