Full Version: 911 Scavenge Side Pressure

As stated ... Does anyone know what pressure might exist on the scavenge side assuming clear lines and no problems with the filter? Doing a reroute of the scavenge line on a /6 conversion (2.7L engine).

Lets consult the holy book of armarments.

3

3

You mean the outlet side of the scavenge pump? When cold it can be very high. Since its a positive displacement pump, if there is avail oil in the case, it will generate whatever output pressure thats required to move it. 911s use a pressure relief in the external thermostat to keep cold oil from blowing up the front cooler. Sorry, I can't find the relief pressure of that t-stat though in any of my docs.

Thanks ... I understand the cold pressure. As far as I can see the only restriction is the oil filter itself.

And the friction loss in the pipes themselves.

Ron,

I am making some shit up here.

But I would think that the scavenge side negative pressures would be negligible. On our round "D": round cars we were more worried about sucking a hose closed that any thing else. Hence we used Good Year hydro hose or typical mesh over teflon hose.

Then again... I'm just guessing.

C

I am making some shit up here.

But I would think that the scavenge side negative pressures would be negligible. On our round "D": round cars we were more worried about sucking a hose closed that any thing else. Hence we used Good Year hydro hose or typical mesh over teflon hose.

Then again... I'm just guessing.

C

And the Lord spake, saying, "First shalt thou take out the Holy Pin. Then shalt thou count to three, no more, no less. Three shall be the number thou shalt count, and the number of the counting shall be three. Four shalt thou not count, neither count thou two, excepting that thou then proceed to three. Five is right out. Once the number three, being the third number, be reached, then lobbest thou thy Holy Hand Grenade of Antioch towards thy foe, who, being naughty in my sight, shall snuff it.

Clayton ....

I agree on the suction side of things ... a collapsed hose would definitely cause a shit pile of problems ... as in "BOOM" from no oil.

On the Grey Ghost, they ran -16 out the flywheel passenger side of the engine, over the top of the tranny, across the starter and up thru the drivers' side sheetmetal to the oil tank (stock 914/6). Line wore thru with the commensurate large oil leak.

To run forward (as in stock), there is no way the -16 fitting will clear the oil return tube and HEs. So, I was going to fabricate a hardline but only had an early aluminum 90 degree fitting (1/2"), but would have to mate it to a late steel tube (5/8") as they changed the fitting on the oil tank to the late size. I was investigating brazing aluminum to steel (I know stupid idea).

Then the thought of JB Weld came to mind (yeh, backyard stuff) and I wondered if the pressure had ever been measured and published.

Another thought was to thread the ID of the 5/8" and screw the 1/2" fitting in with some JB Weld for good measure (there I go thinking again).

Ok, so I need to stop dreaming, get some sleep and re-engineer my engineering problem.

I have some choices as I see it:

1.) Run the line out the flywheel end and around the pass side valve cover, across the front of the engine to the oil tank (thereby re-using the -16 line size)

or

2.) Fabricate a steel line to run much as the stock six mating the early steel fitting to the late tube diameter (Very plausible as I found a steel 90 degree fitting)

or

3.) Take the pass side HE off and beat the shit out of it with a BFH to gain clearance.

I will ask Professor 914 what he thinks later.

Thanks Mr. Towle ... my thoughts exactly after fighting with Ron, Professor 914 and myself Saturday over this.

I agree on the suction side of things ... a collapsed hose would definitely cause a shit pile of problems ... as in "BOOM" from no oil.

On the Grey Ghost, they ran -16 out the flywheel passenger side of the engine, over the top of the tranny, across the starter and up thru the drivers' side sheetmetal to the oil tank (stock 914/6). Line wore thru with the commensurate large oil leak.

To run forward (as in stock), there is no way the -16 fitting will clear the oil return tube and HEs. So, I was going to fabricate a hardline but only had an early aluminum 90 degree fitting (1/2"), but would have to mate it to a late steel tube (5/8") as they changed the fitting on the oil tank to the late size. I was investigating brazing aluminum to steel (I know stupid idea).

Then the thought of JB Weld came to mind (yeh, backyard stuff) and I wondered if the pressure had ever been measured and published.

Another thought was to thread the ID of the 5/8" and screw the 1/2" fitting in with some JB Weld for good measure (there I go thinking again).

Ok, so I need to stop dreaming, get some sleep and re-engineer my engineering problem.

I have some choices as I see it:

1.) Run the line out the flywheel end and around the pass side valve cover, across the front of the engine to the oil tank (thereby re-using the -16 line size)

or

2.) Fabricate a steel line to run much as the stock six mating the early steel fitting to the late tube diameter (Very plausible as I found a steel 90 degree fitting)

or

3.) Take the pass side HE off and beat the shit out of it with a BFH to gain clearance.

I will ask Professor 914 what he thinks later.

Thanks Mr. Towle ... my thoughts exactly after fighting with Ron, Professor 914 and myself Saturday over this.

And the Lord spake, saying, "First shalt thou take out the Holy Pin. Then shalt thou count to three, no more, no less. Three shall be the number thou shalt count, and the number of the counting shall be three. Four shalt thou not count, neither count thou two, excepting that thou then proceed to three. Five is right out. Once the number three, being the third number, be reached, then lobbest thou thy Holy Hand Grenade of Antioch towards thy foe, who, being naughty in my sight, shall snuff it.

Man you crack me up

run away....run away!

I know I can be an ass...

One car I did own had this setup.

The filter was on the passenger side inner fender.

The sump was on the drivers side inner fender.

Two lines came out of the pump, into the filter, then thermo, then off to the front cooler.

One of the lines wrapped neatly around the front of the motor, bolted to the firewall and ran over to the sump.

Rich

One car I did own had this setup.

The filter was on the passenger side inner fender.

The sump was on the drivers side inner fender.

Two lines came out of the pump, into the filter, then thermo, then off to the front cooler.

One of the lines wrapped neatly around the front of the motor, bolted to the firewall and ran over to the sump.

Rich

I don't' like the thought of any scavenge lines running up hill at all.

Then again. I don't know shit about how YOUR six plumbing is laid out.

I do know that the suction side of a dry sump doesn't work for squat if the line makes a loop up and down more than once TO THE PUMP.

In a perfect world. All the evac lines would go downhill only.

Found out the hard way back in the day with a dry sumped Fiat. I blowed that sucker up real good.

And I can have any hose with any weird ends you can imagine done for you on the cheap. In any length and any hose. Would be my pleasure to hook you up my friend. I keep offering. But you no play.. Wassup wid dat?

A simple reach around will be payment enough. (must use nitril gloves this time)

Jo mudder from anudder muder.

Hey Ron. You have any pics of said mod?

Then again. I don't know shit about how YOUR six plumbing is laid out.

I do know that the suction side of a dry sump doesn't work for squat if the line makes a loop up and down more than once TO THE PUMP.

In a perfect world. All the evac lines would go downhill only.

Found out the hard way back in the day with a dry sumped Fiat. I blowed that sucker up real good.

And I can have any hose with any weird ends you can imagine done for you on the cheap. In any length and any hose. Would be my pleasure to hook you up my friend. I keep offering. But you no play.. Wassup wid dat?

A simple reach around will be payment enough. (must use nitril gloves this time)

Jo mudder from anudder muder.

Hey Ron. You have any pics of said mod?

Ok Clayton ... here you go ...

Specs:

'74 2.0 converted sometime before 1987 to a 2.7L CIS flat six. Carerra tensioner upgrade. Permatune CDI unit (mounted in trunk). Original /6 Oil Tank, engine tin and HEs. Engine has not been run since 1990. Suspension consists of 911 front with "S" brakes and Koni Reds. Sway bar in place but not hooked up (no drop links). Rear is Bilstein adjustable perches with 160 lb springs. Tranny is sideshifter with 911 flanges and inner CV hubs.

Was originally Silver but repainted a Metallic Grey (supposedly a BMW color). Hell hole solid, no rust noticeable any other place. Funky panel cutout in rear trunk floor for access to the starter (dumb shit).

The evaluation:

Car was parked due to what the PO thought was a fire. Turns out to be an oil leak in the scavenge line. Whoever did the conversion used -16 to run the line to the flywheel end of the engine over the top of the tranny thru the /6 sheetmetal to the oil tank. Besides making crimping bends, the vibration wore thru the SS braid and into the rubber core. Not the best idea.

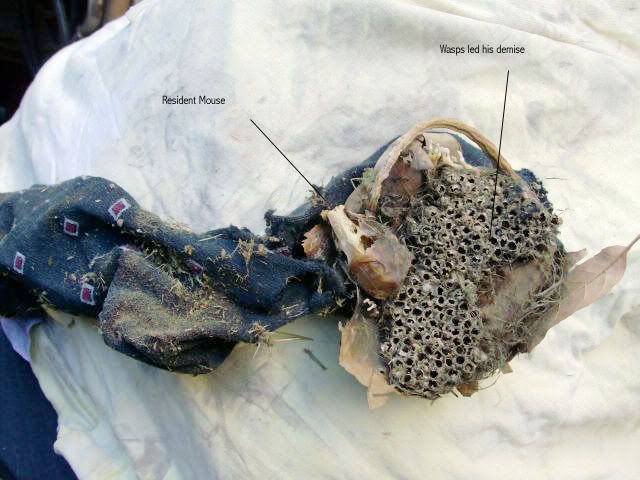

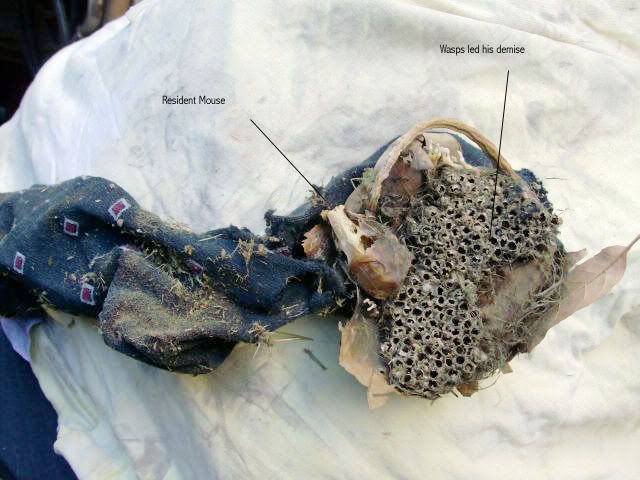

We begin the tour. First the resident POs' friend. Took up residence and was block busted by wasps

Next his residence all cleaned out .. it was packed

Assistance from the resident, somewhat normal, Kraut (Thomas).

His apprentice working on the fuel tank (Mark DAN). Sorry Dan.

We begin the images.

Specs:

'74 2.0 converted sometime before 1987 to a 2.7L CIS flat six. Carerra tensioner upgrade. Permatune CDI unit (mounted in trunk). Original /6 Oil Tank, engine tin and HEs. Engine has not been run since 1990. Suspension consists of 911 front with "S" brakes and Koni Reds. Sway bar in place but not hooked up (no drop links). Rear is Bilstein adjustable perches with 160 lb springs. Tranny is sideshifter with 911 flanges and inner CV hubs.

Was originally Silver but repainted a Metallic Grey (supposedly a BMW color). Hell hole solid, no rust noticeable any other place. Funky panel cutout in rear trunk floor for access to the starter (dumb shit).

The evaluation:

Car was parked due to what the PO thought was a fire. Turns out to be an oil leak in the scavenge line. Whoever did the conversion used -16 to run the line to the flywheel end of the engine over the top of the tranny thru the /6 sheetmetal to the oil tank. Besides making crimping bends, the vibration wore thru the SS braid and into the rubber core. Not the best idea.

We begin the tour. First the resident POs' friend. Took up residence and was block busted by wasps

Next his residence all cleaned out .. it was packed

Assistance from the resident, somewhat normal, Kraut (Thomas).

His apprentice working on the fuel tank (

We begin the images.

The remainder

No pics of the oil line routing.

Paint will probably polish out pretty well.

Engine turns over (Thanks to the Porsche Gods). Replacement of fuel lines, possibly fuel pump, filter and accumulator ... clean out of CIS system ... reroute scavenge oil line, replace filter, 9 quarts of oil and He'll be ready for a start.

Save your Confederate Money .... The Grey Ghost will ride again!!!

No pics of the oil line routing.

Paint will probably polish out pretty well.

Engine turns over (Thanks to the Porsche Gods). Replacement of fuel lines, possibly fuel pump, filter and accumulator ... clean out of CIS system ... reroute scavenge oil line, replace filter, 9 quarts of oil and He'll be ready for a start.

Save your Confederate Money .... The Grey Ghost will ride again!!!

Slits, why not just keep what the PO did but secure the line so it doesn't get cut? No reason at all that line can't run up & over the engine. Just use appropriate cable clamps. Im not one to want to add fittings but if you're paranoid you could add a AN bulkhead feedthrough where it passes though the sheetmetal.

I don't' like the thought of any scavenge lines running up hill at all.

I think slits is talking about the outlet side of the scavange pump (before the conversation turned to the inlet side). The one that come out of the passenger side not the driver side inlet under the oil cooler. Its under positive pressure at all times. Doesn't matter if it runs up/down/sideways. Its half full of air bubbles since the scavange/pressure ratio is > 1. Long winding returns help deaerate the oil (seriously)

(seriously)

Your right about the inlet side. Needs to flow downhill and is under vacuum.

I don't' like the thought of any scavenge lines running up hill at all.

I think slits is talking about the outlet side of the scavange pump (before the conversation turned to the inlet side). The one that come out of the passenger side not the driver side inlet under the oil cooler. Its under positive pressure at all times. Doesn't matter if it runs up/down/sideways. Its half full of air bubbles since the scavange/pressure ratio is > 1. Long winding returns help deaerate the oil

Your right about the inlet side. Needs to flow downhill and is under vacuum.

You are correct about the OUTLET of the scavenge pump ... that's what this discussion was all about.

The reason I don't like the original routing of the line ... I had to remove the AN fittings to get the line out of the car, the line was subject to abrasion when the support failed and the bends it had to make were not really conducive to long life of the line (spelled kinked) ... Sorry, my race car training says you don't do crap like that.**

**That said, I was pissed enough after perforating my hands (with leather gloves) on the stainless shards that stick out of AN line to just do a Mickey Mouse job (Yeh Zois ... everything I do is MM) with JB weld.

Actually, I know that oil runs back into the bottom of the case on shut down of the engine from the scavenge line. I also know that the pressure developed can blow an oil cooler on cold startup (ever had an oil bath?). I was just curious if the pressure (if any) had ever been measured at normal running temp.

So now, I will have a steel line made up to run between the HEs and oil return tubes (like a stock 6) and make a flex line (like the short hose on a 6) so the engine can be dropped with the line intact.

If I do it right the first time ... I won't have to redo it.

The reason I don't like the original routing of the line ... I had to remove the AN fittings to get the line out of the car, the line was subject to abrasion when the support failed and the bends it had to make were not really conducive to long life of the line (spelled kinked) ... Sorry, my race car training says you don't do crap like that.**

**That said, I was pissed enough after perforating my hands (with leather gloves) on the stainless shards that stick out of AN line to just do a Mickey Mouse job (Yeh Zois ... everything I do is MM) with JB weld.

Actually, I know that oil runs back into the bottom of the case on shut down of the engine from the scavenge line. I also know that the pressure developed can blow an oil cooler on cold startup (ever had an oil bath?). I was just curious if the pressure (if any) had ever been measured at normal running temp.

So now, I will have a steel line made up to run between the HEs and oil return tubes (like a stock 6) and make a flex line (like the short hose on a 6) so the engine can be dropped with the line intact.

If I do it right the first time ... I won't have to redo it.

Send me your dimensions and what ends you need. I will have it made up for you.

OR. I will get you the parts and YOU put the ends on. Either way. If I can help you. I will.

AND I need to get my PET book back if at all possible after you are done with this car. I have needed that sucker several times as of late.

Let me know what ya need.

Claytonobitch

OR. I will get you the parts and YOU put the ends on. Either way. If I can help you. I will.

AND I need to get my PET book back if at all possible after you are done with this car. I have needed that sucker several times as of late.

Let me know what ya need.

Claytonobitch

The pressure can be VERY high at cold startup. If the car sets without being started for 2-3 weeks the sump will fill with oil with little if any oil in the tank.

Crank it over for 45-60 sec to get oil back into the tank.

There is a pressure relief valve in a proper Porsche oil filter and it is built to withstand

a the high pressure surge that comes with the above scenario.

This is no place to screw around.

If you don't have an aux cooler, just pretend those lines are joined together and it runs across the front of the motor. That is -12 stuff.

Crank it over for 45-60 sec to get oil back into the tank.

There is a pressure relief valve in a proper Porsche oil filter and it is built to withstand

a the high pressure surge that comes with the above scenario.

This is no place to screw around.

If you don't have an aux cooler, just pretend those lines are joined together and it runs across the front of the motor. That is -12 stuff.

BTW, some years back a guy tole me he rigged a OP gauge to his scavenge side to check. 165 psi on a cold start up. I've seen 8 bar (120psi) briefly on the pressure side at cold start and the pressure side of the pump has about 40% less volume capability than the scavenge side.....then there was the time I blew up my aux cooler.........Many things I've learned haven't come easily.

Thanks JP

The Fix .......

Part of an original /6 hardline

Braised fitting to flexline

One more fitting to braise to hardline

Now, just some funky fabrication by ???

Engine mount

Accel bellcrank mount

And that's the rest of the story ...............

Part of an original /6 hardline

Braised fitting to flexline

One more fitting to braise to hardline

Now, just some funky fabrication by ???

Engine mount

Accel bellcrank mount

And that's the rest of the story ...............

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please click here.