I am getting ready to turbo my 1.8L engine. And I already know that you can't turbo a 914. But, what i would like to know is what are good cars to get turbo's off of?

I am looking for a small turbo that will spool quickly. Looking to run about 7 to 10 pounds of boost.

What turbo'd cars will give me a good turbo to use? I have been looking for ones on ebay, but don't really want to buy one there. I don't mind buying a used one, so going to the junkyard and getting one is definitely an option.

Which turbo?

Full Version: What turbo should I buy?

I would think something matched to your displacement, a VW Beetle turbo or an audi TT they both are 1.8 or 2.0's. Your going to have to do something about getting it more fuel on boost and retarding the timing.

Check out the other turbo T'4's on this board.

http://www.914world.com/bbs2/index.php?sho...c=65883&hl=

Check out the other turbo T'4's on this board.

http://www.914world.com/bbs2/index.php?sho...c=65883&hl=

I would think something matched to your displacement, a VW Beetle turbo or an audi TT they both are 1.8 or 2.0's. Your going to have to do something about getting it more fuel on boost and retarding the timing.

Check out the other turbo T'4's on this board.

http://www.914world.com/bbs2/index.php?sho...c=65883&hl=

I'm not the guy with the answer but I do know it isn't quite that easy. An early 944 turbo SUCKS ass. They have a lot of lag. When the turbo S came out the hot side was changed and the impeller was also changed, giving it a much quicker spool and adding some additional power. The turbo needs to be spec'd and matched to where you want the power much like any other engine component

I think i have read all the turbo stuff there is on this site, lots of different setups and ideas. I plan on a draw-through setup, not blow through. Blow-through is much more complicated, and i won't be running high boost, so no need for an intercooler. So....draw-through seems to be the best setup for me.

hmmmmm.

iamchappy....should i rethink my setup and go with blow through, is that what the hmmmm is for?

I would like the turbo to spool around 2000rpm and last till about 4500.

I would like the turbo to spool around 2000rpm and last till about 4500.

You planning on running carbs and a turbo? side draft carb and turbo?

I sold a Garret Turbo off of a Chrysler 2.2 (from a daytona...) to someone about 9 years ago to use in a 914, IIRC they had pretty good results with it.

There are several tricks to get a turbo to spool up quickly, too. Not sure how good of ideas some of them are...

The one that comes to mind is having a granger one-way valve with the adjustable pressure spring inside. Put it inline between the pressure source and the wastegate after setting it to the pressure you want your turbo to be spooled at.

I sold a Garret Turbo off of a Chrysler 2.2 (from a daytona...) to someone about 9 years ago to use in a 914, IIRC they had pretty good results with it.

There are several tricks to get a turbo to spool up quickly, too. Not sure how good of ideas some of them are...

The one that comes to mind is having a granger one-way valve with the adjustable pressure spring inside. Put it inline between the pressure source and the wastegate after setting it to the pressure you want your turbo to be spooled at.

I am considering using my corvair turbo and side draft carb setup some day. They are not too expensive to get. Used on a 2.7L engine originally.

I would look in the junk yard for a turbo from a Mitsubishi Eclipse.

iamchappy....should i rethink my setup and go with blow through, is that what the hmmmm is for?

I would like the turbo to spool around 2000rpm and last till about 4500.

That is me thinking outloud. I once considered doing a carb sidedraft setup.

I cant help you with that though as i've never done it.

Just wondering iamchappy, thats all.

I plan on running carb and turbo. I don't want to have to run a side draft carb becuase i have a nice set of EMPI HPMX 40's that i might be able to use. If the setup works better with side draft i would run a side draft, but if i can use one of the HPMX's or maybe even both(that would be cool, kind of like a four barrel carb) that would be the best since i already have them.

Right now i have found a guy on craigslist that is selling a turbo kit from lowbugget.com, comes with turbo(garrett T3) and other goodies. I would highly modify that kit to work, mainly i would use the turbo and the exhuast piece that goes to the turbo. The exhuast is actually made for a VW bug, but i would cut it up to use some of the flanges and tubes. The exhaust piece would be modified to run off the 914's exhaust.

I plan on running carb and turbo. I don't want to have to run a side draft carb becuase i have a nice set of EMPI HPMX 40's that i might be able to use. If the setup works better with side draft i would run a side draft, but if i can use one of the HPMX's or maybe even both(that would be cool, kind of like a four barrel carb) that would be the best since i already have them.

Right now i have found a guy on craigslist that is selling a turbo kit from lowbugget.com, comes with turbo(garrett T3) and other goodies. I would highly modify that kit to work, mainly i would use the turbo and the exhuast piece that goes to the turbo. The exhuast is actually made for a VW bug, but i would cut it up to use some of the flanges and tubes. The exhaust piece would be modified to run off the 914's exhaust.

I think this would be a perfect match for your drivetrain, it has a little lag but when it kicks in it should give you the extra power you are looking for.

Click to view attachment

Click to view attachment

I am getting ready to turbo my 1.8L engine. And I already know that you can't turbo a 914. But, what i would like to know is what are good cars to get turbo's off of?

I am looking for a small turbo that will spool quickly. Looking to run about 7 to 10 pounds of boost.

What turbo'd cars will give me a good turbo to use? I have been looking for ones on ebay, but don't really want to buy one there. I don't mind buying a used one, so going to the junkyard and getting one is definitely an option.

Which turbo?

My 2.0/4 is CIS injected and I changed the 944/ K-26Turbo that was on it when EvilEd built it to a NOS K-26 that was used on a few different Audi's like the 5000S 2.2

It spools up much quicker than the 944/K-26 right at 1800 rpm's and keeps pulling up to 5500 rpms were my rev limiter is set.

You also have to think about your ignition and putting a timing retard control on it so you can retard your timing under boost.

My set up has very little lag and the power is very linear, smooth and Fasssst!!

I think this would be a perfect match for your drivetrain, it has a little lag but when it kicks in it should give you the extra power you are looking for.

Click to view attachment

That one should kick in at about 90,000 RPM's and be good up to about 200,000 RPM's.

If you you want to run a significant level of boost you may want to run a J&S Safeguard. Knock sensing timing control that trims timing on each cylinder individually.

http://www.jandssafeguard.com/

http://www.jandssafeguard.com/

I think this would be a perfect match for your drivetrain, it has a little lag but when it kicks in it should give you the extra power you are looking for.

Click to view attachment

Hook the motor to the impiler shaft and use it for thrust.

How about this one? Internal wastegate.

http://cgi.ebay.com/ebaymotors/New-Mitsubi...%3A1|240%3A1318

http://cgi.ebay.com/ebaymotors/New-Mitsubi...%3A1|240%3A1318

better design, too. =o) (IMHO)

http://cgi.ebay.com/ebaymotors/T3-T4-Hybri...A1%7C240%3A1318

this one has floating bearings... less resistance than bushing types means quicker spooling.

this one has floating bearings... less resistance than bushing types means quicker spooling.

Small hijack, but may help this thread as well as me, what books are good resources to read about how to set up a turbo system, engine parameters and management systems?

how about a link?

http://www.ztechz.net/id4.html

it's for another application, but the physics are still the same. =o)

http://www.ztechz.net/id4.html

it's for another application, but the physics are still the same. =o)

Would have replied sooner, but i had to work today.

Nein14, that rpm range would be perfect for what i want to do. 1800 to 5500 is perfect.

I would like to run at least 7.5 psi, and maybe up to 10psi(thats a big maybe)

On the first link to an ebay turbo, what is the giant gold piece hanging off the turbo, i see those on a lot of turbo's but haven't been able to identify what it actually is? What is it?

Thanks for the links everybody. I have been reading these two links if it helps anyone

Turbo Torque

Turbo Type I engine

The second link is the one i have read and reread, that setup is what i am going for. Also, its a vw engine, so that helps a lot too!

The only issue i am having is since i am using a draw-through setup, the turbo has to have a CARBON seal, a dynamic seal won't work, at least thats what ive read. The gas would eat through the dynamic seal. I'll have to ask the people selling the turbo's on ebay if they have carbon seals, and if they don't, can they be rebuilt to have a carbon seal!

How do you know when you buy a turbo what rpm it will spool up at and when it will trail off?

Ebay Turbo with wet float bearings

With this ebay turbo, i really like this one, but it is a stage 3 turbo, isn't that a little large for my motor? Also, the 25-35psi is peak performance, i take it i can externally wastegate it to my preferred 7.5 to 10?

Thanks so much everyone. Once i find the right turbo, i will start a build thread. I have to finish off my hell hole area first and then start with the turbo.

Nein14, that rpm range would be perfect for what i want to do. 1800 to 5500 is perfect.

I would like to run at least 7.5 psi, and maybe up to 10psi(thats a big maybe)

On the first link to an ebay turbo, what is the giant gold piece hanging off the turbo, i see those on a lot of turbo's but haven't been able to identify what it actually is? What is it?

Thanks for the links everybody. I have been reading these two links if it helps anyone

Turbo Torque

Turbo Type I engine

The second link is the one i have read and reread, that setup is what i am going for. Also, its a vw engine, so that helps a lot too!

The only issue i am having is since i am using a draw-through setup, the turbo has to have a CARBON seal, a dynamic seal won't work, at least thats what ive read. The gas would eat through the dynamic seal. I'll have to ask the people selling the turbo's on ebay if they have carbon seals, and if they don't, can they be rebuilt to have a carbon seal!

How do you know when you buy a turbo what rpm it will spool up at and when it will trail off?

Ebay Turbo with wet float bearings

With this ebay turbo, i really like this one, but it is a stage 3 turbo, isn't that a little large for my motor? Also, the 25-35psi is peak performance, i take it i can externally wastegate it to my preferred 7.5 to 10?

Thanks so much everyone. Once i find the right turbo, i will start a build thread. I have to finish off my hell hole area first and then start with the turbo.

On the first link to an ebay turbo, what is the giant gold piece hanging off the turbo, i see those on a lot of turbo's but haven't been able to identify what it actually is? What is it?

There is a little diaphraghm in there that pushes on the rod. There is a vacuum/boost line that goes to the manifold that builds pressure inside of the one side of the diaphragm. the other side has the rod on it, which, in turn, opens the wastegate to release exhaust gasses that would otherwise be spinning the impellers.

How do you know when you buy a turbo what rpm it will spool up at and when it will trail off?

The last link that I posted has more information on the other links to the left. there is a very lengthy explanation of impeller ratios, airflow, Volumetric Efficiency, and how they all tie together for which size of turbo to get. EDIT: Direct link to turbo selection page. http://www.ztechz.net/id7.html

Ebay Turbo with wet float bearings

With this ebay turbo, i really like this one, but it is a stage 3 turbo, isn't that a little large for my motor? Also, the 25-35psi is peak performance, i take it i can externally wastegate it to my preferred 7.5 to 10?

stage 3 doesn't really mean much when you aren't using it for the application that it was designed for. the compressor sizes and flow maps for a given turbo will show you more than the designated 'stage 3'.

Yes, you can wastegate it to 7.5 to 10.

Thanks for the answers RJMII, i had to read through that link twice to understand it. Id understand more of it if i had a turbo'd engine on a dyno. Im more of a hands on learner, but i seem to comprehend most of the link.

The turbo on ebay with the wet float bearings is the one i will probably buy. I will have to replace the seal in it, thats the only problem.

If a turbo is a T3, will any T3 carbon seal fit in it? I found a kit on ebay to change out the seal, and wanted to know if it will work with the turbo.

Thanks everybody!!!!

The turbo on ebay with the wet float bearings is the one i will probably buy. I will have to replace the seal in it, thats the only problem.

If a turbo is a T3, will any T3 carbon seal fit in it? I found a kit on ebay to change out the seal, and wanted to know if it will work with the turbo.

Thanks everybody!!!!

I think a Garrett GT2052 is a pretty good match for your application. These are nice because they have such a high compressor efficiency for their frame size, 77%.

Here's the map. The yellow line is 10psi from 1800rpm to 6000rpm. The green line is 8psi from 1800 to 6000rpm. Both are estimated at 90% volumetric efficiency.

Click to view attachment

Here's the map. The yellow line is 10psi from 1800rpm to 6000rpm. The green line is 8psi from 1800 to 6000rpm. Both are estimated at 90% volumetric efficiency.

Click to view attachment

Some thoughts for you- Chappy beat me to the link to my project, so you've got that. Our engines are OLD SCHOOL- 2 valve heads, push rods, air cooled, and the cam in our engine is lame from the start. Air flow is airflow? Not really. A modern 4 valve water cooled DOHC motor will move alot more air more quickly and spool a turbo up sooner. Don't go to big on the turbo! I thought a subie wrx turbo would be fine, that goes on a 2.0 motor, mine was a 2.0 motor- sure, it would start to make some boost from 2k rpm, but to see the 7-10 psi you're looking for, it would not hit that target till nearly 4k rpm, and while the ride from 4k to 5.5k was pretty quick, the trip up to 4k was less fun than expected.

The best tool you can have to do this project is knowledge- not just asking on a board what might work, what have you done, but reading and gaining a deep understanding of how it works and why... I'm not being mean here, but if you're not sure what the gold thingy on the turbo is and what it does, you need to go to school, you're not even close to ready to start cutting and welding.

Here is your list of required reading:

Maximum Boost, by Corky Bell

Street Turbocharging, by Mark Warner

Turbo maps link: http://www.rbracing-rsr.com/turbotech.html

Memorize both of these and you'll be ready to ask the right questions and make the right decisions. Neither will have specific answers to questions you will have, but you'll know what questions to ask, and how to understand the answers you come up with.

Turbos make power 2 ways- 1, thru the speed of the exhaust gas hitting the vanes, and 2, by the heat in the exhaust. So in general, if the turbo you are considering from an OEM car was mounted close to the exhaust port on the head, you can bet the speed and heat of the exhaust from that motor were considreations by the OEM in choosing that turbo- so mounting it farther away from the head will reduce the speed/heat getting into the turbo, and reduce the performance of the turbo.

And, if you're doing a draw thru turbo, you'll need one with a carbon seal. These were far more common of turbos in OEM's in the 80's, so finding a "good" used one usually means finding one that at one time was good, and now is used up. Also, the engineering of the housings and wheels will be 20 yrs behind the current models available. Many currently offered turbos can be re-built with a carbon seal.

Research and consider water injection as well, to help cool the charge air, since an intercooler is not an option with draw thru. Its an odd balance, in that we want higher egt's to help spool the turbo, but to much egt will fry the head and drop valves seats.

Do your home work. Read alot. Surf alot. The internet is your friend.

The best tool you can have to do this project is knowledge- not just asking on a board what might work, what have you done, but reading and gaining a deep understanding of how it works and why... I'm not being mean here, but if you're not sure what the gold thingy on the turbo is and what it does, you need to go to school, you're not even close to ready to start cutting and welding.

Here is your list of required reading:

Maximum Boost, by Corky Bell

Street Turbocharging, by Mark Warner

Turbo maps link: http://www.rbracing-rsr.com/turbotech.html

Memorize both of these and you'll be ready to ask the right questions and make the right decisions. Neither will have specific answers to questions you will have, but you'll know what questions to ask, and how to understand the answers you come up with.

Turbos make power 2 ways- 1, thru the speed of the exhaust gas hitting the vanes, and 2, by the heat in the exhaust. So in general, if the turbo you are considering from an OEM car was mounted close to the exhaust port on the head, you can bet the speed and heat of the exhaust from that motor were considreations by the OEM in choosing that turbo- so mounting it farther away from the head will reduce the speed/heat getting into the turbo, and reduce the performance of the turbo.

And, if you're doing a draw thru turbo, you'll need one with a carbon seal. These were far more common of turbos in OEM's in the 80's, so finding a "good" used one usually means finding one that at one time was good, and now is used up. Also, the engineering of the housings and wheels will be 20 yrs behind the current models available. Many currently offered turbos can be re-built with a carbon seal.

Research and consider water injection as well, to help cool the charge air, since an intercooler is not an option with draw thru. Its an odd balance, in that we want higher egt's to help spool the turbo, but to much egt will fry the head and drop valves seats.

Do your home work. Read alot. Surf alot. The internet is your friend.

Ah, thems the books I was inquiring about  If I ever do this I would like to do a remote on like you did, Otto.

If I ever do this I would like to do a remote on like you did, Otto.

Ah, thems the books I was inquiring about

Ah, Good Doctor. Not that you need more reading for your non-existent spare time, but both books were very helpful in the 914T project. The remote mount has its issues, but its benefits as well. I really liked the way everything seemed to fall into place with out looking smashed into its location. Oil and plugs are still (almost) easily accessible. The fun part can be seen in the photo below- I was at Road America this past summer, and happened into Joe Gearin, who checked out the car and liked it, so much so that he invited me to put it by the tent for a day. Standing across the street, with an ice cream treat, watching folks check out the car, seeing the boost gauge in the tach, the intercooler under the hood, and scratch their heads wondering where the turbo was... priceless.

I got both of the books from Amazon for the cost of one of them at Boarders ($36 shipped). Looking forward to expanding my mind. Maybe I will turbo my bus in the future.

I agree that the remote turbo looks like it belongs without clogging up the engine bay.

I agree that the remote turbo looks like it belongs without clogging up the engine bay.

I got both of the books from Amazon for the cost of one of them at Boarders ($36 shipped). Looking forward to expanding my mind. Maybe I will turbo my bus in the future.

I agree that the remote turbo looks like it belongs without clogging up the engine bay.

From lag stand point there is almost none, and it is much much quicker spool up.

Much more efficent to mount the turbo in the engine bay besides the cool factor

BTW there is no issue with heat

QUOTE

but if you're not sure what the gold thingy on the turbo is and what it does, you need to go to school, you're not even close to ready to start cutting and welding.

Not to be mean here either ottox914, but not knowing what the gold thing was, does not mean im not ready to cut and weld. I have welding down, ive taken every welding class at my community college(took them last summer when i got my welder). Before those classes my dad was teaching me at his shop, who is a professional welder and cnc operator.

I have read the book on turbo's i bought from barnes and nobles, which is Maximum Boost(the one you mentioned) front to back, twice.

im already in school, i just don't study cars, cars are a hobby and i don't have the kind of money or time to just keep taking classes at college about cars: on top of all the chem classes i already have, plus working part-time to pay for school, you gotta learn some things on your own(just my opinion). I study Organic Chemistry, which is way more difficult than any car.

The Turbo will be in the engine bay, for anyone who cares.

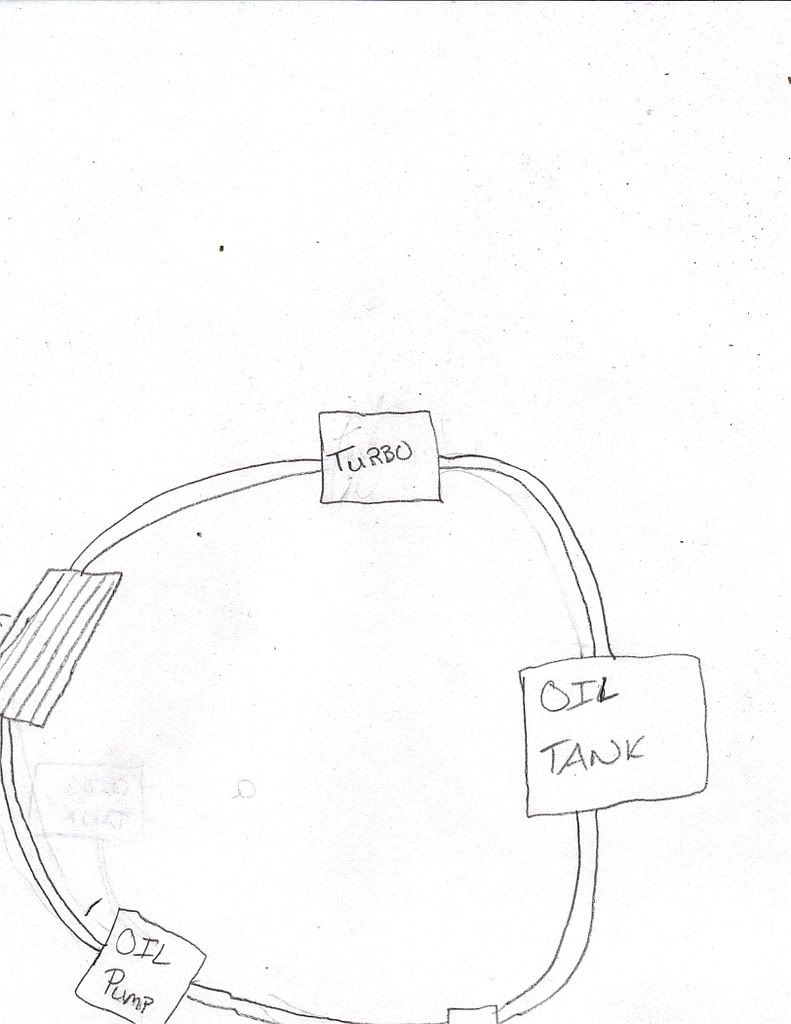

I have been playing around with some ideas on cooling the turbo. Since the turbo is oil cooled, I was thinking of running the turbo on its own oil circuit(if you want to call it that), instead of running it off the engines oil, leave that oil for the engine.

What my plan is: The Turbo Oil Circuit

1. Have an oil tank that holds about 1 to 2 quarts of oil

2. Then have an electric oil pump to pump the oil through the turbo.

3. The setup would be and oil tank and filter before the pump, and then the oil cooler would be after the pump and then into the turbo.

4. Since the oil is pulled out of the turbo by gravity, an oil line would run back to the oil tank, and the process starts all over.

I figured that this way, the turbo would have its own oil setup(probably different oil than the engine as well) and receive clean, cooled down oil.

Heres a crude drawing of what i want to do:

Since my scanner didn't scan correctly, the thing in the bottom right corner of the image would be the oil filter and the thing in the top left would be the oil cooler!!

My son mildly ported his 2.5 sti heads with stock size valves and they flowed 260 cfm on the intake at .400 valve lift. A big port jdm ported head flows around 290-300 cfm. Thats better than most v8 sb chebbys. I have some edlebrock 2.02 intake valve heads that advertise 170 cfm for a sbc. You really need to know or find out the cfm requirements of the motor you are boosting. There are at least two well known companies that turbo t1 motors and they are using some 1.6-2.0 motors so that would be a good place to lurk when you have time. As someone already said the farther from the exhaust port the harder it is to spool the turbo but the easier to cool the intake charge. On most turbo applications the shorter the intake path that is kept to ambient or lower temps is the most efficient. 6-10 lbs is a reasonable attempt without really messing with the stock na motor.

You will find a na 2.5 dohc suby will have more torque and be a cheaper and more reliable motor and probably give better gas mileage and no oil leaks and valves to adjust.

Just putting fresh oil to the turbo isn't a big deal. If the oil temps are kept good for the motor they are no problem for the turbo.

Depending on the oil pressure to the turbo you will need a very small orfice to restrict the oil or it will flood the turbo and go into the intake track and cause detonation. You may think high performance autos are simple but you will never learn all the things you need to know about high performance if you aren't interested in studying all you can find on the subject. Just get a education and buy the best car you can afford and build a 100 mile an hour kart it will be simpler.

I took welding and machine shop in college. 40 years ago. I've been welding ever since. I still know people that are better machinist and welders than me. Taking classes are just the beginning and those skills come to the best by really just spending many hours doing it.

Trust me I'm 64 the books are the cheapest way to do the best you can the first time but experience can't be studied, it must be acquired.

My son is a me, He hot rods a suby sti. He also read the max boost after I gave it to him and he thought it was a good general turbo book but the really high per. turb suby, evo, us, australian and european guys are way past that but everyone needs a simpler starting place.

You will find a na 2.5 dohc suby will have more torque and be a cheaper and more reliable motor and probably give better gas mileage and no oil leaks and valves to adjust.

Just putting fresh oil to the turbo isn't a big deal. If the oil temps are kept good for the motor they are no problem for the turbo.

Depending on the oil pressure to the turbo you will need a very small orfice to restrict the oil or it will flood the turbo and go into the intake track and cause detonation. You may think high performance autos are simple but you will never learn all the things you need to know about high performance if you aren't interested in studying all you can find on the subject. Just get a education and buy the best car you can afford and build a 100 mile an hour kart it will be simpler.

I took welding and machine shop in college. 40 years ago. I've been welding ever since. I still know people that are better machinist and welders than me. Taking classes are just the beginning and those skills come to the best by really just spending many hours doing it.

Trust me I'm 64 the books are the cheapest way to do the best you can the first time but experience can't be studied, it must be acquired.

My son is a me, He hot rods a suby sti. He also read the max boost after I gave it to him and he thought it was a good general turbo book but the really high per. turb suby, evo, us, australian and european guys are way past that but everyone needs a simpler starting place.

Apparently everyone thinks that im not willing to learn(which i am, thats why im on this website and reading every piece of info on turbos on the web), screw it. No more turbo. Ill follow the advice charliew gave, to basically give up, don't learn 914's, buy a new car, and leave the work for the pro's. Sorry, but everyone(even the pros) have to start somewhere, and thats what im trying to do.

I understand the point of showing me all the different aspects of turbo's and such, it makes you think about what your doing. which i truly thank everyone for.

I understand the point of showing me all the different aspects of turbo's and such, it makes you think about what your doing. which i truly thank everyone for.

I think everyone needs to play nice here. The lad asked some questions and was treated by some, IMHO, tersely. No one means ill here, I know, but on line you sometimes come across as more crass than you probably wished.

Dont be discouraged. But, even I knew what the gold thingy was

Dont be discouraged. But, even I knew what the gold thingy was

Apparently everyone thinks that im not willing to learn(which i am, thats why im on this website and reading every piece of info on turbos on the web), screw it. No more turbo. Ill follow the advice charliew gave, to basically give up, don't learn 914's, buy a new car, and leave the work for the pro's. Sorry, but everyone(even the pros) have to start somewhere, and thats what im trying to do.

I understand the point of showing me all the different aspects of turbo's and such, it makes you think about what your doing. which i truly thank everyone for.

I think you are willing to learn. =o) ask more questions.

Thats the whole reason i started this thread, learn turbo's, motors and whatever else i can. Thats the whole reason i bought a vw bug and porsche 914, learn cars. Its pretty easy to buy tools, and replace parts on a car(like alternators, starters, etc), but the technical stuff(like turbos, rebuilding motors, suspension geometry) is what i am trying to learn, and just about every other person on this site. Doesn't matter who you are, if you are on this site you are either teaching or learning, and even the teaches learn a few things now and then. Thats life, you never stop learning!!!!!!! Being only 19, theres no way to know everything and understand everything about cars, thats the point of asking questions.

I got some answers that i wanted and then some answers that i would have never even conceived of hearing from other 914 owners.

I have never been more pissed off after reading this piece of advice. I don't car who you are, DON'T EVER tell anyone to give up what their doing and take the easy way out or the simpler way out.

The 914 is not my first build, my vw baja bug was my first build

Full roll cage, 10in travel shocks in front, 14in travel shocks in back, racing seats, harnesses, adjustable beam, boxed rear trailing arms, and big mo-fo tires, stock 1600cc dual port engine

If anyone here knows anything about baja bugs, i started with a super beetle if that helps you understand the skill set i have. I finished that project and needed another one, so i came here. Of course, i had help on that car as well, I had help from people on thesamba.com to build that car.

Ill try to keep my questions to pm's from now on.

Thanks to all the people that helped answer my questions and even the ones that showed pictures of their own setups. Thanks again!!

OK, now im done

I got some answers that i wanted and then some answers that i would have never even conceived of hearing from other 914 owners.

I have never been more pissed off after reading this piece of advice. I don't car who you are, DON'T EVER tell anyone to give up what their doing and take the easy way out or the simpler way out.

QUOTE

Just get a education and buy the best car you can afford and build a 100 mile an hour kart it will be simpler.

The 914 is not my first build, my vw baja bug was my first build

Full roll cage, 10in travel shocks in front, 14in travel shocks in back, racing seats, harnesses, adjustable beam, boxed rear trailing arms, and big mo-fo tires, stock 1600cc dual port engine

If anyone here knows anything about baja bugs, i started with a super beetle if that helps you understand the skill set i have. I finished that project and needed another one, so i came here. Of course, i had help on that car as well, I had help from people on thesamba.com to build that car.

Ill try to keep my questions to pm's from now on.

Thanks to all the people that helped answer my questions and even the ones that showed pictures of their own setups. Thanks again!!

OK, now im done

Dude- sorry we/me rubbed you the wrong way. Chill a little! I did not mean to imply you couldn't weld and fabricate, just using that as an example. Here's another one- if you want to slap a turbo on something, and follow a path already known, and I hate to even suggest this, look for a Miata. The motor is boost friendly from the factory, and boosting one of those has been done 1000's of times. Any question you could think of has probably been answered, and proven, many times before. Another option might be: boost your Baja. There's been lots more done to boost bug motors than 914 motors. Boost that one up, and apply what you learn to designing and making your 914 system. While I'm not into the bug/baja world as you are, I would think building the suspension on your baja project involved a little more "been there done that" info you could get from others (like the samba that you mention) that had gone there before you, than is available on the turbo a type IV project. I suspect you added a few twists of your own to the bug project, as most of us would, but I would also think there were others who had done the same thing, and some off the shelf parts known to work for your application that were available. Adding a turbo to a 30 yr old motor that wasn't designed for one and has no currently made kits can be a fun project, but with out doing LOTS of homework and being willing to blow stuff up, could be a frustrating project. If you are comfortable welding and want a cool 914 project, rather than focus your efforts on making a turbo type IV motor work, maybe look to do the subie swap. If you do it with the subie trans, you get a known boost friendly motor, the trans to support it, and you can get creative making mounts, figuring out the radiator and shift linkage, and have a heck of a car when you're done.

While we're more 914's than bugs over here, we're all air cooled. How about a couple pics of your Baja.

Everyone likes to show off their toys a little now and then.

While we're more 914's than bugs over here, we're all air cooled. How about a couple pics of your Baja.

Everyone likes to show off their toys a little now and then.

Just a quick comment; I'd look to keeping the boost in the 5-7psi range. More boost makes manging the heat more difficult in an air cooled motor without an intercooler. The water injection as suggested for this application is worth looking into, IMO. Besides, you really won't notice the second 5 psi nearly as much as the first 5psi.

Andys

Andys

After some pm's i had with RJMII, i am gonna look into and aftermarket efi system, instead of running carbs. The carbs that i already bought for the 914 will go onto my baja bug, ill need different intakes, but at least they don't go to waste that way. Or maybe even sell them and put that money into the 914 efi + turbo setup.

Megasquirt may be the way i will go. I got a little more reading about microsquirt to do, but i think megasquirt might be the best choice.

If i go efi, the turbo will go from the original idea of draw-through to a blow through setup. That way i could run the intercooler and keep temps lower.

Im mainly in the stage right now of deciding on efi or carbs. Sooner or later my 914 will have a turbo. I have to wait for a bonus i get from work to start purchasing parts. Woodman's is an awesome part-time job, grocery store in the midwest area, mainly Wisconsin and northern Illinois.

Sorry for flipping out, just don't like advice of giving up at all. Ottox914 and chairliew, my apologies, you are only trying to help. thank you!

Megasquirt may be the way i will go. I got a little more reading about microsquirt to do, but i think megasquirt might be the best choice.

If i go efi, the turbo will go from the original idea of draw-through to a blow through setup. That way i could run the intercooler and keep temps lower.

Im mainly in the stage right now of deciding on efi or carbs. Sooner or later my 914 will have a turbo. I have to wait for a bonus i get from work to start purchasing parts. Woodman's is an awesome part-time job, grocery store in the midwest area, mainly Wisconsin and northern Illinois.

Sorry for flipping out, just don't like advice of giving up at all. Ottox914 and chairliew, my apologies, you are only trying to help. thank you!

Just a quick comment; I'd look to keeping the boost in the 5-7psi range. More boost makes manging the heat more difficult in an air cooled motor without an intercooler. The water injection as suggested for this application is worth looking into, IMO. Besides, you really won't notice the second 5 psi nearly as much as the first 5psi.

Andys

I certainly have not found that true, even 8 is a big jump from 5, 10 is a leap and 14 is a plunge!

10, probably won't happen on my car, maybe put it there once to see what will happen. 7.5 to 8, would be what im shooting for.

Click to view attachment

Just a quick comment; I'd look to keeping the boost in the 5-7psi range. More boost makes manging the heat more difficult in an air cooled motor without an intercooler. The water injection as suggested for this application is worth looking into, IMO. Besides, you really won't notice the second 5 psi nearly as much as the first 5psi.

Andys

I certainly have not found that true, even 8 is a big jump from 5, 10 is a leap and 14 is a plunge!

Just a quick comment; I'd look to keeping the boost in the 5-7psi range. More boost makes manging the heat more difficult in an air cooled motor without an intercooler. The water injection as suggested for this application is worth looking into, IMO. Besides, you really won't notice the second 5 psi nearly as much as the first 5psi.

Andys

I certainly have not found that true, even 8 is a big jump from 5, 10 is a leap and 14 is a plunge!

Just a quick comment; I'd look to keeping the boost in the 5-7psi range. More boost makes manging the heat more difficult in an air cooled motor without an intercooler. The water injection as suggested for this application is worth looking into, IMO. Besides, you really won't notice the second 5 psi nearly as much as the first 5psi.

Andys

I certainly have not found that true, even 8 is a big jump from 5, 10 is a leap and 14 is a plunge!

I'm with Chappy on this one. The first five was fun, 5-10 was more fun, and when the motor is built up, we'll see how 10-15 feels...

From "street turbocharging" by Warner, page 95.

1-5psi no intercooler or water injection

5-12psi intercooler only

12> intercooler and water injection.

Chappy has come up with an elegant solution to getting air thru an intercooler used in a mid engine application. My intercooler is the standard unit off a wrx, and has a metal plenum below it holding a 1000 cfm fan to pull air thru the intercooler across the whole core. On a 90 degree day, I'd have intake temps around 30 degrees over ambient. On cooler days, the increase was 10-20 degrees. After an hour or so at highway speeds, the IC would heat soak, even with the fan on, and temps would continue to rise to maybe 30-40 above ambient, but at highway speeds at steady throttle there was no boost involved, so slightly elevated temps were not a concern. I was considering adding water injection, and may still do so, but for now plans are for the built motor and a new plenum that seals better, and has 2- 1100 cfm puller fans in it. I'll try the new 2 fan system before getting much farther into the WI install. Of course, this will vary with the type of motor, compression ratio, fuel used, amount of boost, and a 100 other things. Best to walk before you run.

After some pm's i had with RJMII, i am gonna look into and aftermarket efi system, instead of running carbs. The carbs that i already bought for the 914 will go onto my baja bug, ill need different intakes, but at least they don't go to waste that way. Or maybe even sell them and put that money into the 914 efi + turbo setup.

Megasquirt may be the way i will go. I got a little more reading about microsquirt to do, but i think megasquirt might be the best choice.

If i go efi, the turbo will go from the original idea of draw-through to a blow through setup. That way i could run the intercooler and keep temps lower.

Im mainly in the stage right now of deciding on efi or carbs. Sooner or later my 914 will have a turbo. I have to wait for a bonus i get from work to start purchasing parts. Woodman's is an awesome part-time job, grocery store in the midwest area, mainly Wisconsin and northern Illinois.

Sorry for flipping out, just don't like advice of giving up at all. Ottox914 and chairliew, my apologies, you are only trying to help. thank you!

Before you commit to an EFI injection system which is very $$$, by the time you done with your conversion you will be in the cost range of doing a 3.0 /6 911 motor.

Another option is to use Bosch CIS injection which is what my Turbo is using, which is the same design principle as the Porsche 930 onlty a 4 cyl. version.

Very very reliable, and a cost effective conversion. I run 10lbs. of boost on the street on premium and have run 14 lbs. on 100 octane on the track with the Caroll Water Injection system I have and the car does not have a intercooler.

This can also has a 3 qt. accusump and a front mount oil cooler and has been running this set up since 2002 thats 7 years !!!!!!

Very very reliable and can be driven as a daily driver!

Geat a copy of Excellence magazine June 02' there is a 4 page article on the car

Good luck with your project keep me posted on your progress.

We should have a separate turbo 914 forum just for this stuff. There is so much. Thanks for sharing

Some pics I poached

Just a quick comment; I'd look to keeping the boost in the 5-7psi range. More boost makes manging the heat more difficult in an air cooled motor without an intercooler. The water injection as suggested for this application is worth looking into, IMO. Besides, you really won't notice the second 5 psi nearly as much as the first 5psi.

Andys

I certainly have not found that true, even 8 is a big jump from 5, 10 is a leap and 14 is a plunge!

You guys are taking my comment all wrong; that's probably my fault

From nothing to 5 psi is pretty dramatic. A 5 psi delta is another matter.

Built my first tubo conversion in '69 using a '63 Olds Jetfire turbo setup that employed alcohol injection, and several more after that including a 914-4. No one made any of the great controls we have today, so we made our own. I'm not very current anymore.

Andys

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please click here.