Somewhere earlier I saw a comment that Jake had recommended using 911 Valve Adjusters in the Type-4 engine... Or maybe he had recommended against it. I can't remember.

Anybody out there have experience in this? My adjusters and adjuster nuts were pretty gnarled when I got my car a few years ago. Now with bi-monthly adjustments, I'm looking to replace them.

Will the 911 adjusters fit the existing rocker arms? Do I need the same nuts? If I go ahead with this, should my properly adjusted valves run quieter? And is there any advantage to replacing the springs?

As a result of some moderate leaky valve guides, my plans are to have the heads re-built this winter. Should I wait until the heads are rebuilt, or is there any reason I shouldn't go ahead with the adjusters, nuts and springs right now?

Any thoughts?

My thanks.

Eric Read

Full Version: 911 Valve Adjusters for my Type-4 2.0L?

you'll need a set of 1.7 rockers and then you must shave .040 off the underside where the swivel would contact when drawn up tight.

I.M.O. was a great improvement, kinda' removes some of the "thrashing machine" v.w. sound.

mike

I.M.O. was a great improvement, kinda' removes some of the "thrashing machine" v.w. sound.

mike

OT - can't help on the adjusters, but i like the viper blue - here's mine -

Click to view attachment

Click to view attachment

The viper blue really looks good!!!

Our SCCA FP race car is also Viper Blue

As for the 911 adjusters... I run them on every turn key we build and have since about 1997..

As for the 911 adjusters... I run them on every turn key we build and have since about 1997..

you'll need a set of 1.7 rockers and then you must shave .040 off the underside where the swivel would contact when drawn up tight.

I.M.O. was a great improvement, kinda' removes some of the "thrashing machine" v.w. sound.

mike

...would you have a photo of the removal of 1mm of material off the rocker as an example?

you'll need a set of 1.7 rockers and then you must shave .040 off the underside where the swivel would contact when drawn up tight.

I.M.O. was a great improvement, kinda' removes some of the "thrashing machine" v.w. sound.

mike

...would you have a photo of the removal of 1mm of material off the rocker as an example?

i don't, sorry, i'm sure someone will have one. just mic. the thickness and take a flat .040 of the bottom.(the swivel will need that room to sit up in) it's also been advised here that grinding side to side is best.

mike

Our SCCA FP race car is also Viper Blue

As for the 911 adjusters... I run them on every turn key we build and have since about 1997..

Jake;

Do you sell the 911 adjusters as a kit or set up so I wouldn't have to shave the rockers? I didn't see it in your store, but I may have been overlooking the obvious...

It seems to me like it is a good idea to make this modification. Is there any reason why I should not consider such a mod?

My thanks

Eric

Doesn't this potentially change the valvetrain geometry? Lots of intricate measurements and perhaps resizing of the pushrods required?

Kev

Kev

Doesn't this potentially change the valvetrain geometry? Lots of intricate measurements and perhaps resizing of the pushrods required?

Kev

Yes, and Jake has an EXCELLENT procedure on very accurately setting the valve train geometry and how to determine the necessary pushrod length.

-Josh2

you'll need a set of 1.7 rockers and then you must shave .040 off the underside where the swivel would contact when drawn up tight.

I.M.O. was a great improvement, kinda' removes some of the "thrashing machine" v.w. sound.

mike

You need to remove .060 off the underside instead of .040

Doesn't this potentially change the valvetrain geometry? Lots of intricate measurements and perhaps resizing of the pushrods required?

Kev

Yes, and Jake has an EXCELLENT procedure on very accurately setting the valve train geometry and how to determine the necessary pushrod length.

-Josh2

Nevermind, I found it! :doh:

Doesn't this potentially change the valvetrain geometry? Lots of intricate measurements and perhaps resizing of the pushrods required?

Kev

No, this does not change the geometry. By clearancing the rocker by .060, the contact point of the adjuster to the valve stem (the swivel foot) will be in the same place as the contact point of the old adjuster screw. Therefore, no geometry adjustment is needed.

Now if you are building a new engine then yes, you should check the geometry. But on an engine with the geometry already set, this modification would not make a change.

Doesn't this potentially change the valvetrain geometry? Lots of intricate measurements and perhaps resizing of the pushrods required?

Kev

No, this does not change the geometry. By clearancing the rocker by .060, the contact point of the adjuster to the valve stem (the swivel foot) will be in the same place as the contact point of the old adjuster screw. Therefore, no geometry adjustment is needed.

Now if you are building a new engine then yes, you should check the geometry. But on an engine with the geometry already set, this modification would not make a change.

So Chris, do you have an extra set of rockers that have been shaved .060? Is there anybody that does have these? I'm pretty handy with a wrench and a BFH, but I sure don't have a shop full of tools needed to create such a precise clearance.

As of yet, no one has relplied that it's a bad idea. So why doesn't someone create a kit that includes the rockers, adjusters and maybe replacement springs?

Eric

It does not need to be precise, you can do it with an angle or die grinder. You should try to minimize the number of sharp edges/stress risers, especially ones that cut across the rocker. Better to grind along the length of the rocker which, of course, is more difficult.

It does not need to be precise, you can do it with an angle or die grinder. You should try to minimize the number of sharp edges/stress risers, especially ones that cut across the rocker. Better to grind along the length of the rocker which, of course, is more difficult.

You've got to understand, power tools and I do not get along very well. Usually ending up in crying, massive amounts of blood and a garage that looks like it hosted a slasher movie.

Click to view attachment

Okay, so if I'm reading the comments right, there is no appreciable geometry change? Cool.

I guess the next question would be if this is an upgrade that could be performed on the engine while it's still in the car????

I'm not about to embark on this myself, I -just- got it running again. But it would be interesting to know anyway...

-Josh2

I guess the next question would be if this is an upgrade that could be performed on the engine while it's still in the car????

I'm not about to embark on this myself, I -just- got it running again. But it would be interesting to know anyway...

-Josh2

Okay, so if I'm reading the comments right, there is no appreciable geometry change? Cool.

I guess the next question would be if this is an upgrade that could be performed on the engine while it's still in the car????

I'm not about to embark on this myself, I -just- got it running again. But it would be interesting to know anyway...

-Josh2

I see no reason why this couldn't be accomplished with the engine in the car. The valve covers are easily accessable.

I was able to change out my push rod tubes with the engine in the car, and that necessitated the removal of the rocker arms. So this should really be no more difficult than that.

Eric

Umm you really need to redo the valve geometry. Anytime you change something in the valve train you need to do it

I disagree. If you grind the rockers down ~.06" to allow enough room for the swivel feet to swivel, and you set your lash as you always have been in the past, then nothing has changed as far as the geometry is concerned. The adjuster contact face is .006" away from the valve stem and, because of that, the rocker angle relative to the valve stem is the same that it was before the porsche adjusters were installed. So, assuming the geom was correct from the start, there is no need to re-do it. You could use anything as the adjuster and the geom would remain the same because it is not a function of the adjuster shape, just a function of the distance/angle between the rocker and the valve stem (which hasn't changed).

Now if you used shims to space out the rocker shaft instead of grinding the rocker faces, then yes, you would need to re-do the geometry.

-Chris

Now if you used shims to space out the rocker shaft instead of grinding the rocker faces, then yes, you would need to re-do the geometry.

-Chris

I would say the geometry would need to be verified as there are instances where the pre-geometry could have been set up with a pushrod thats too long to work properly with the swivel foot adjuster. This is because of the thickness of the swivel foot when compared to the stock adjuster.

Rule #1: Never assume anything.

Rule #2: Verify everything.

Rule #1: Never assume anything.

Rule #2: Verify everything.

When you say "work properly", what do you mean? Are you talking about the swivel foot contacting the rocker even with .060" removed at some point during the rockers' sweep? I agree that this needs to be checked but is this really checking the geometry? If there is binding, then yes, you would have to shim the rockers out or adjust the pushrod length which would entail re-setting the geometry.

But if there is no binding, and the geometry was fine from the start, then you are still fine because from a geometrical standpoint, nothing has changed.

But if there is no binding, and the geometry was fine from the start, then you are still fine because from a geometrical standpoint, nothing has changed.

As Jake mentioned you need to check it. You are making a change in the valve train and your assuming the valve geo is going to be right and if you don't check it you'll never know. The .060 you remove from under the rocker is only a starting point as most of the time its enough but sometimes you need to remove a bit more or shim the rocker shafts but you'll never know unless you check it. Even though you can achieve proper valve lash your geometry could be off.

I urge you to draw it out. If you don't have to add shims in order for the swivel adjuster to not bind through the sweep of the rocker, and the geometry was set correct from the start then the geometry will still be correct because nothing has changed. The rocker shaft is in the same position therefore the rocker is pivoting about the same point, the pushrod is the same length because you didn't change it and since the adjuster face is still .006" away from the valve stem as it was before the swap to swivels, then the geometry is still the same.

If you have doubts about your geometry being set correctly, then by all means check it. But if you are confident in your work then checking the geom is wasting your time because all you have done is changed what the adjuster looks like, not where it is.

-Chris

If you have doubts about your geometry being set correctly, then by all means check it. But if you are confident in your work then checking the geom is wasting your time because all you have done is changed what the adjuster looks like, not where it is.

-Chris

The goal of proper valve geometry is the aliment of the valve stem and the adjuster at haft valve lift. You could change that aliment by making any change in the valve train which you did by switching to the 911 adjusters. By not checking it to make sure your only assuming your geometry is still right. It very well could be but you'll never know unless it is checked.

Okay, if you won't draw it out . . .

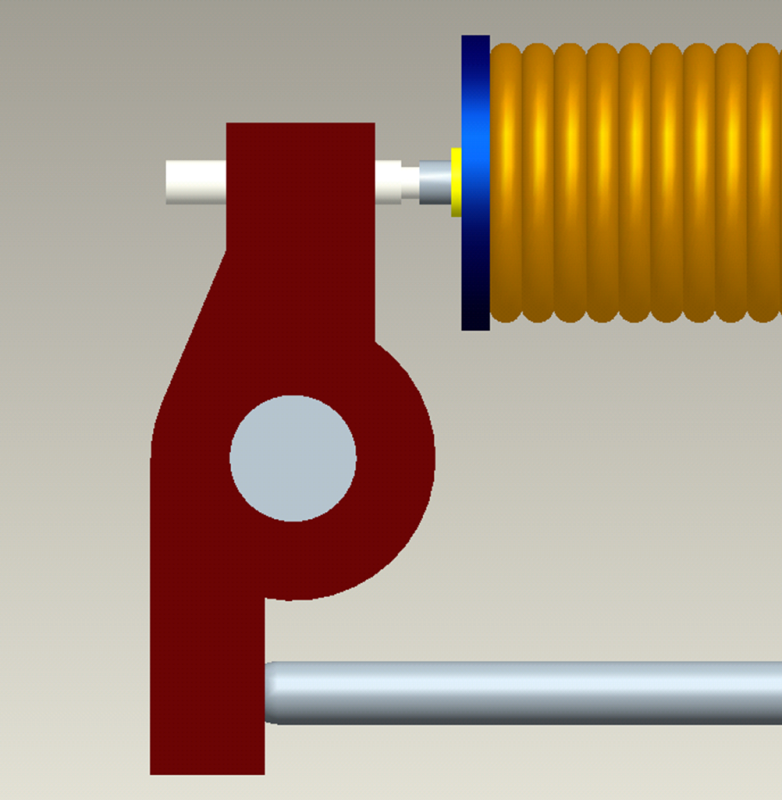

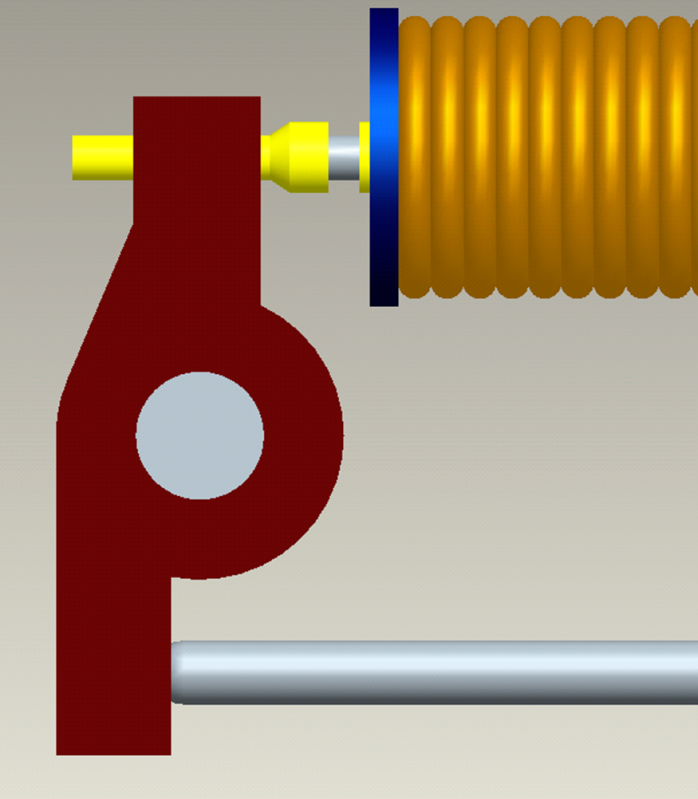

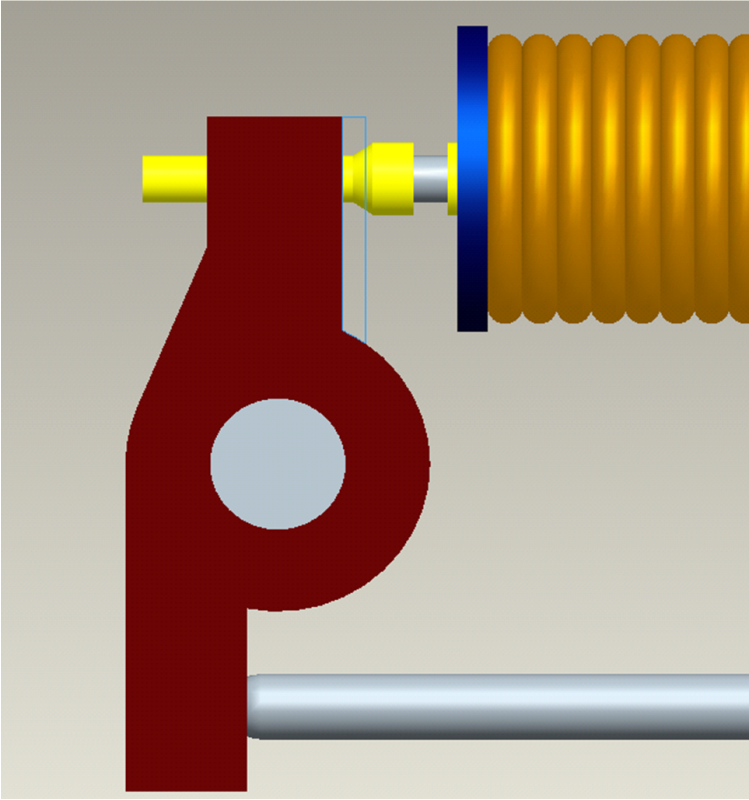

Crude drawing of the valve train, approximates what the t4 has close enough to prove a point.

Stock adjuster set with appropriate geometry (adjuster inline with the valve stem) at half lift:

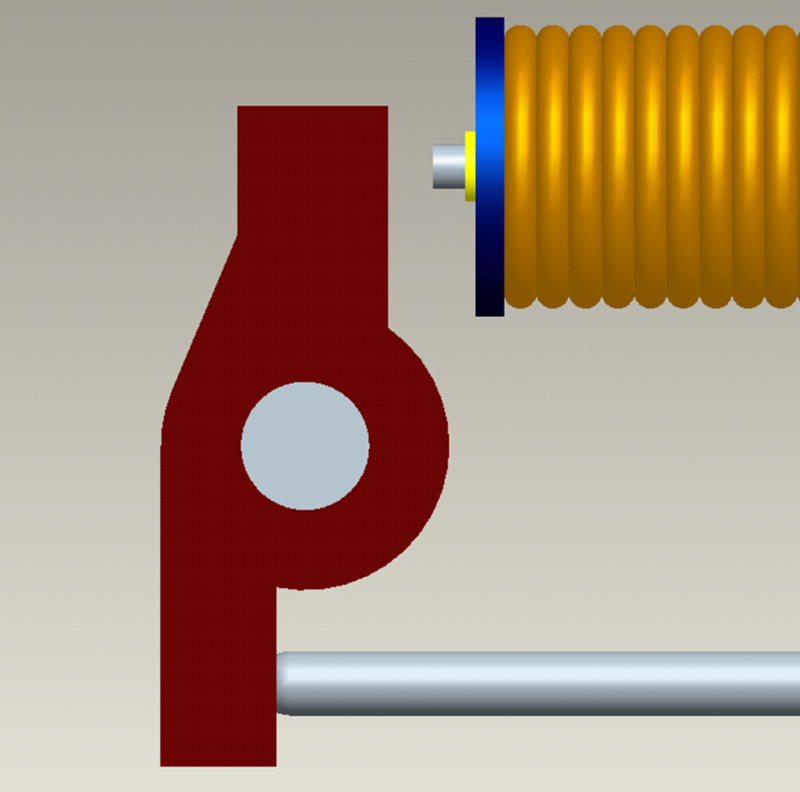

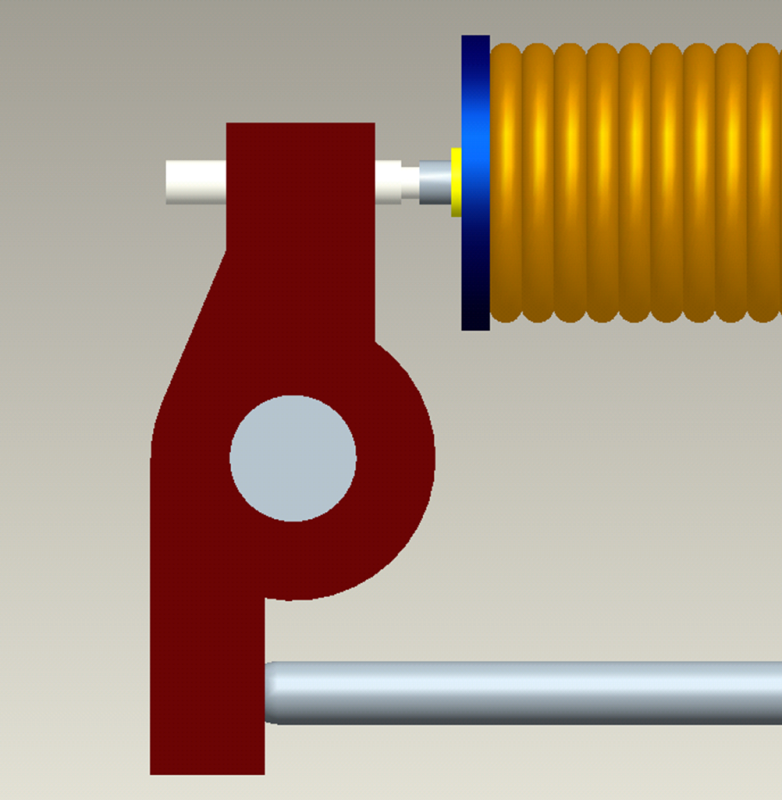

Now, pretend for a minute that the valve spring will just stay compressed so that when you pull the stock adjuster, nothing moves. Geometry is still the same. Cam is still rotated to half lift for that rocker, lifter is the same length, pushrod is the same length, rocker is rotated about the shaft (which hasn't moved) by the same amount:

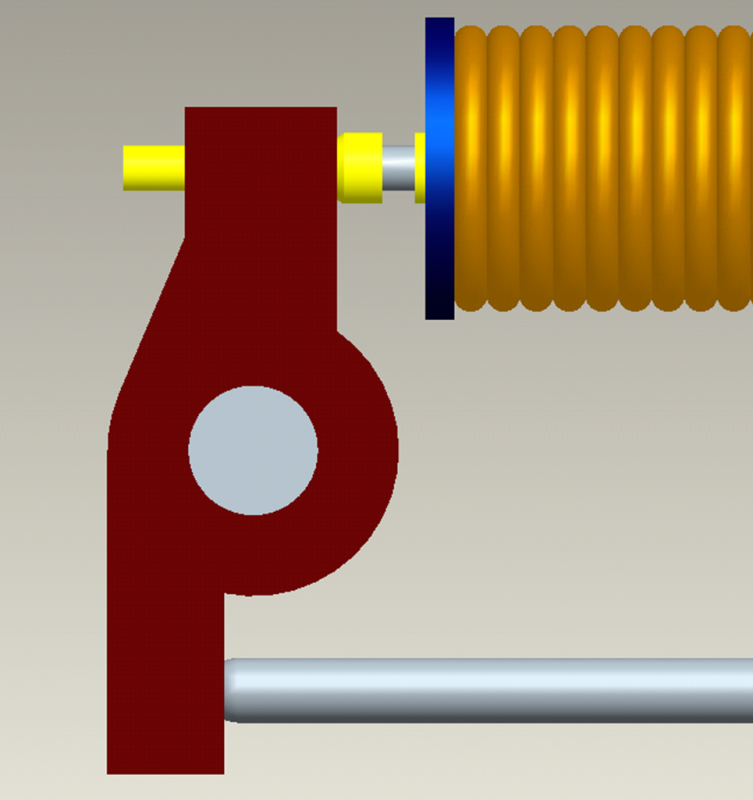

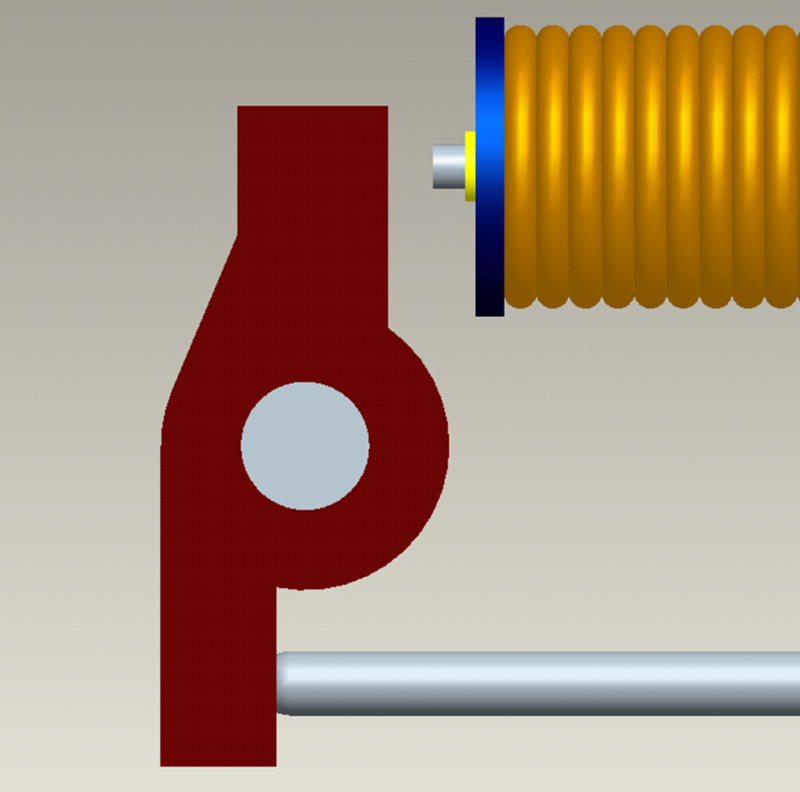

Now, put the porsche adjuster in. You can see that by simply swapping what the adjuster looks like does nothing to change the geometry:

Now the problem is, as you can see in the above picture, that the porsche adjuster foot will interfere with the stock rocker, which is why it needs to be clearanced (blue box below):

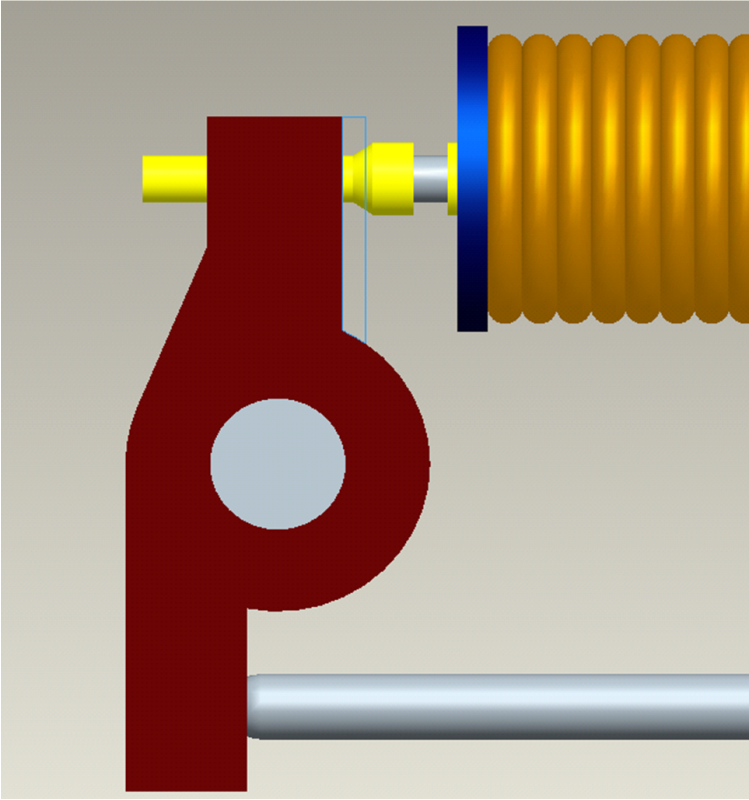

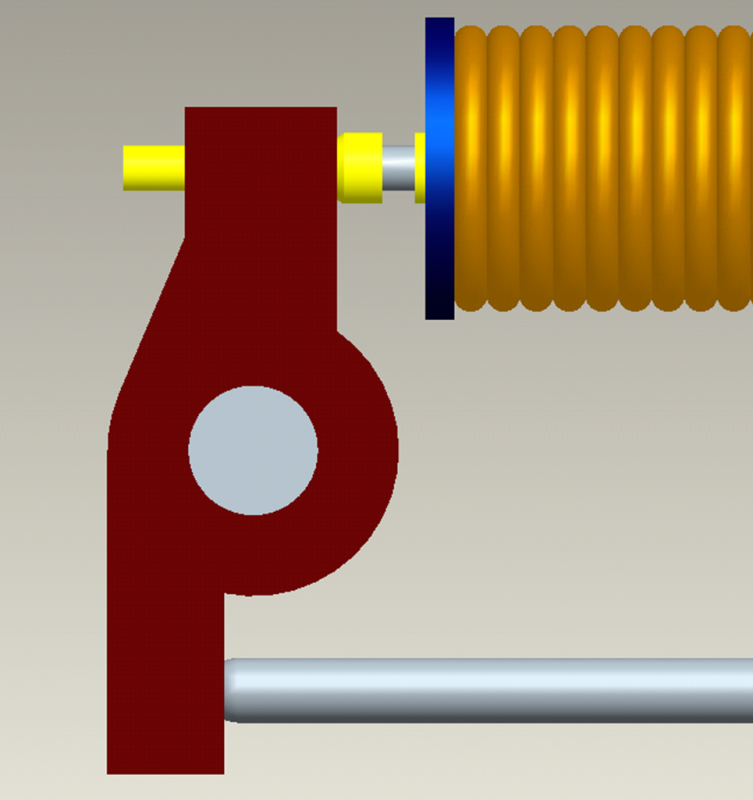

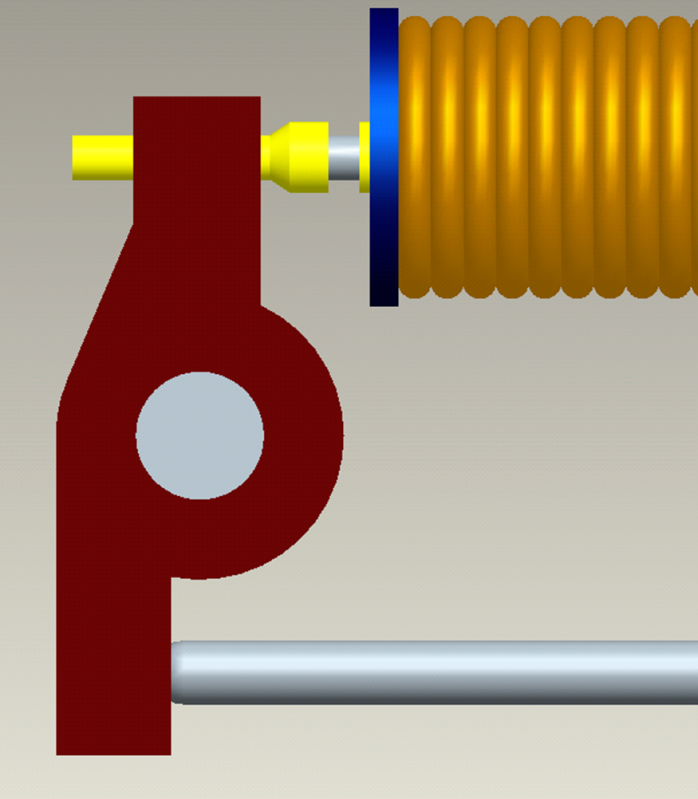

Final product:

The only thing that changed in any of these pictures was what the adjuster looked like, and clearancing some of the rocker to allow for proper adjuster function. Everything else is fixed, as it is in your engine, because simply changing what the adjuster looks like does not affect the length of the pushrod, position of the rocker shaft, etc. Set the lash the same between the stock adj and the porsche adj to get the contact face in the same plane relative to the valve stem and everything else will fall in to place.

Now if you have to shim to get enough clearance for the adjuster to work properly then you are moving the location of the rocker shaft relative to the valve stem and cam so you will definitely need to change your geometry.

Crude drawing of the valve train, approximates what the t4 has close enough to prove a point.

Stock adjuster set with appropriate geometry (adjuster inline with the valve stem) at half lift:

Now, pretend for a minute that the valve spring will just stay compressed so that when you pull the stock adjuster, nothing moves. Geometry is still the same. Cam is still rotated to half lift for that rocker, lifter is the same length, pushrod is the same length, rocker is rotated about the shaft (which hasn't moved) by the same amount:

Now, put the porsche adjuster in. You can see that by simply swapping what the adjuster looks like does nothing to change the geometry:

Now the problem is, as you can see in the above picture, that the porsche adjuster foot will interfere with the stock rocker, which is why it needs to be clearanced (blue box below):

Final product:

The only thing that changed in any of these pictures was what the adjuster looked like, and clearancing some of the rocker to allow for proper adjuster function. Everything else is fixed, as it is in your engine, because simply changing what the adjuster looks like does not affect the length of the pushrod, position of the rocker shaft, etc. Set the lash the same between the stock adj and the porsche adj to get the contact face in the same plane relative to the valve stem and everything else will fall in to place.

Now if you have to shim to get enough clearance for the adjuster to work properly then you are moving the location of the rocker shaft relative to the valve stem and cam so you will definitely need to change your geometry.

What is the desired "finish" measurement of the shaved rocker? Every stock 1.7 rocker I've measured has a different original reading, so taking 0.060 is relative to the starting measurement. Shouldn't all of them be the same finish measurement? Or does it matter?

Thanks...Dan

Thanks...Dan

Way to go. Add these drawings to the save the technical stuff thread!

Is the only difference in the 1.7 and 1.8 rocker the size of the threaded post? 8mm vs 10mm? Is it worth the difference on a daily driver to change out the rocker arm just to get the 911 screws?

Also does shimming mean add shim washers under the rocker arm assembly, to move it further away from the motor?

Is the only difference in the 1.7 and 1.8 rocker the size of the threaded post? 8mm vs 10mm? Is it worth the difference on a daily driver to change out the rocker arm just to get the 911 screws?

Also does shimming mean add shim washers under the rocker arm assembly, to move it further away from the motor?

If you need something a bit stronger than the 911 ones, check these out:

http://cbperformance.com/catalog.asp?ProductID=115

http://cbperformance.com/catalog.asp?ProductID=115

http://www.914world.com/bbs2/index.php?showtopic=103826

some here think genueniune Porsche is what we need to stay with, due to past experiences.

some here think genueniune Porsche is what we need to stay with, due to past experiences.

I here the CB ones are ok. It's the empi and bugpack stuff you need to stay away from. Don't know first hand though.

.............I wonder If , when you compair the two types of adjusters, You understand the actual differences, and ultimate functionality..........Murray Mcafee

I here the CB ones are ok. It's the empi and bugpack stuff you need to stay away from. Don't know first hand though.

The Porsche ones are good. First class. The CB ones are "OK". The rest are cr*p, more or less. You care about your work? Use the Porsche ones. You just wanna brag (I can use that word, right? I mean he doesn't have a patent on it or anything, does he?) you have "swivel feet" and don't give a rat's arse about the quality of the work? Use the CB ones. Personally, for a stocker, I don't see any reason to use anything than good quality stock adjuster screws and nuts. Mind you, there are some

el cheapo screws out there that aren't worth the price of the postage to get 'em to you.

The Cap'n

Sorry double post

............Keep Looking.......and compairing...........you guys are not there yet.

The Porsche ones are good. First class. The CB ones are "OK". The rest are cr*p, more or less. You care about your work? Use the Porsche ones. You just wanna brag (I can use that word, right? I mean he doesn't have a patent on it or anything, does he?) you have "swivel feet" and don't give a rat's arse about the quality of the work? Use the CB ones. Personally, for a stocker, I don't see any reason to use anything than good quality stock adjuster screws and nuts. Mind you, there are some

el cheapo screws out there that aren't worth the price of the postage to get 'em to you.

The Cap'n

The CB ones are stronger than the porsche ones. Look at the thickness of the metal where the porsche ones are clearanced for the swivel of the foot, that's where they break on a missed shift.

Real experience with racing motors says the CB ones beat the Porsche ones. ALL of my 914s have them.

Unless you'd like to argue that an oil pressure fed adjuster with a larger bearing surface on a thicker shaft is going to be weaker?

In 37 years of working on 911s, I've never seen a broken valve adjuster screw. Rocker arms, for sure, but not the screws. Of course, MY customers don't have catastrophic chain tensioner failures because I take care of them as I should. That's what they pay me for ....................

The Cap'n

The Cap'n

So are you talking about using these things in stock 911 engines or high performance type IV engines?

I have no idea why you even brought up cam chain tensioners here?

I have no idea why you even brought up cam chain tensioners here?

Click to view attachment

Any comments on using these as opposed to "Genuine Porsche" at twice the price?

By the way, CB Performance "Elephant Feet" are about a quarter the price if these.

Any comments on using these as opposed to "Genuine Porsche" at twice the price?

By the way, CB Performance "Elephant Feet" are about a quarter the price if these.

Bump

Those are the same price as the adjusters Jake is selling at the type 4 store. There it also says OEM German 911 Rocker adjusters. -hard to say whether the stock of parts that Porsche takes delivery of are subject to further quality control than the oem part sold directly from the manufacturer?

The difference is we aren't parts whores. We sell what we use and we support it, because we understand it. Looking for cheap price? Won't find it here.

I have a few questions, one is about valve rotation. I thought the valve adjusters are supposed to be off center of the valve stem? This I believe was to rotate the valve slightly so the valve and seat would not collect carbon and repeated wear in the same places. With the 911 swivel adjusters what will make the valves rotate if the swivel adjuster can rotate instead?

Also is the valve lash the same with the 911 adjusters in place?

Thanks in advance for your responses.

Mike

ps: Is .060 enough to remove from the underside of the rocker arm? See photo below.

Click to view attachment

Also is the valve lash the same with the 911 adjusters in place?

Thanks in advance for your responses.

Mike

ps: Is .060 enough to remove from the underside of the rocker arm? See photo below.

Click to view attachment

Clearance them enough so that the feet don't bind during operation. Depending on how much casting (forging?) flash is there, it may be more than .060. Try to finish grinding them with the grind marks not going perpendicular to the length of the rocker, stress risers can be created this way.

The adjuster will still be off the valve axis if it is set up correctly. As the valve is depressed, the foot will still sweep across the valve stem some distance from the valve axis, creating a force/moment that wants to spin the valve.

At least that is the way I sees it.

-Chris

The adjuster will still be off the valve axis if it is set up correctly. As the valve is depressed, the foot will still sweep across the valve stem some distance from the valve axis, creating a force/moment that wants to spin the valve.

At least that is the way I sees it.

-Chris

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please click here.