personally I am not thinking of re-use...

I guess we would need to build it similar to have the same weight/ flex properties, and a vacuum seal....

We could make one piece and solder the diaphram onto it...

Or we could make two pieces that are threaded together..little bit of silicone to ensure a tight seal...

Please measure the inside dimension of the hole in the diaphram so we have that number...

Rich

Full Version: Paging Mueller

Tomorrow I will as its across town to the shop

[QUOTE]There is usually a conversion chart or equation for these testers so Vickers shouldn't be a problem.

Is the copper you test hard or soft?

The Copper we use is in the 200 250 vicker range. The instrument I use is a Leitz Durimet with a Mini Load Hardenss tester.

I don't know how this metal will harden compared to copper. In copper, you soften it by heating then quickly cooling which is the opposite of steel. To harden, I imagine heating to a spefic temperature temperature and cooling at a some determined slow rate.

As for measuring the deflection, I would make a mounting fixture and measuring the deflection with a dial indicator with a weight applied. I would also do this with 3 different weights to insure the amount of deflection throught the full range is correct.

Mark

Is the copper you test hard or soft?

The Copper we use is in the 200 250 vicker range. The instrument I use is a Leitz Durimet with a Mini Load Hardenss tester.

I don't know how this metal will harden compared to copper. In copper, you soften it by heating then quickly cooling which is the opposite of steel. To harden, I imagine heating to a spefic temperature temperature and cooling at a some determined slow rate.

As for measuring the deflection, I would make a mounting fixture and measuring the deflection with a dial indicator with a weight applied. I would also do this with 3 different weights to insure the amount of deflection throught the full range is correct.

Mark

Cool,

would you volunteer to test the diaphram for hardness.

Rich

would you volunteer to test the diaphram for hardness.

Rich

[QUOTE] Cool,

would you volunteer to test the diaphram for hardness.

No problem. PM me and I will give you an address. I would be willing to help or make a test fixture for measuring the deflection. I would need a good one for a reference. I would return this undamaged.

Mark

would you volunteer to test the diaphram for hardness.

No problem. PM me and I will give you an address. I would be willing to help or make a test fixture for measuring the deflection. I would need a good one for a reference. I would return this undamaged.

Mark

I can supply a good diaphram and a junk one (pieces) for testing.

Addy??

Addy??

Progress...I love progress..

So, we have a drawing under way...Geoff, please post the inner diameter of the hole in the diaphram...

And we have a hardness test going on...

Now, how do we verify the actual material...

Correct me if I am wrong...the patent documents do not declare the material???

Does anyone have any contacts at Bosch we could ask for a clear answer??

Oh, and on the inner screw retention part,,,I propose a two piece deal, it could be designed to be a threaded piece that gets screwed through the diaphram..

It would make assembly easier..

We just need to design the piece to be the same shape/material as the original to ensure we have the same reaction properties in the new assembly...

Did that make any sense at all?

Rich

So, we have a drawing under way...Geoff, please post the inner diameter of the hole in the diaphram...

And we have a hardness test going on...

Now, how do we verify the actual material...

Correct me if I am wrong...the patent documents do not declare the material???

Does anyone have any contacts at Bosch we could ask for a clear answer??

Oh, and on the inner screw retention part,,,I propose a two piece deal, it could be designed to be a threaded piece that gets screwed through the diaphram..

It would make assembly easier..

We just need to design the piece to be the same shape/material as the original to ensure we have the same reaction properties in the new assembly...

Did that make any sense at all?

Rich

It's an effin spring...

So you need:

1. Material-

2. Material Thickness- makes a big difference on rate

3. Similar diaphragm dimensions

4. Heat treat for durability-forming issues.

For a quick and dirty material properties calc, cut a strip, measure the width, and thickness. Clamp in a vise and Measure the distance from the wall to the point where the force will be applied. Add weight or force and measure the deflection.

Calculate the modulus of elasticity and look up material.

Use the cantilever deflection equation to calculate the modulus...

deflection= load*length^3 (cubed)/

3* modulus* width *(height^3 (cubed)/12)

There ya go... Won't be exact but I bet it will get you within 85% of the correct value.

So you need:

1. Material-

2. Material Thickness- makes a big difference on rate

3. Similar diaphragm dimensions

4. Heat treat for durability-forming issues.

For a quick and dirty material properties calc, cut a strip, measure the width, and thickness. Clamp in a vise and Measure the distance from the wall to the point where the force will be applied. Add weight or force and measure the deflection.

Calculate the modulus of elasticity and look up material.

Use the cantilever deflection equation to calculate the modulus...

deflection= load*length^3 (cubed)/

3* modulus* width *(height^3 (cubed)/12)

There ya go... Won't be exact but I bet it will get you within 85% of the correct value.

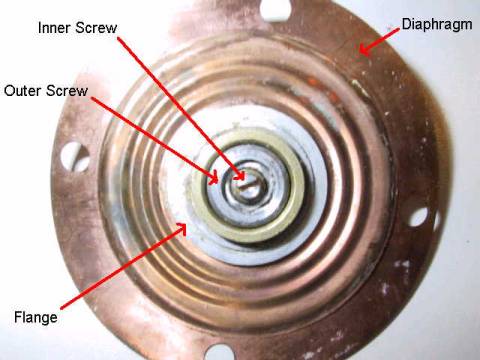

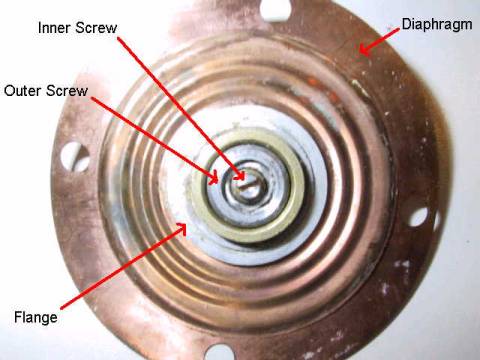

OK. I got the diaphragm from Jeff today. This is the first one I have seen (except for in pictures). I was very surprised at how small the stamped pleates are in this diaphragm. They seem much smaller than they seem from other pictures. Especially the outermost (widest) pleat. It's probably only 3 or 4 mils tall, and is barely even discernable as a pleat.

compared to the pics from Brad Anders' site:

His seem much larger and more pronounced. But maybe it's just the lighting.

Demick

His seem much larger and more pronounced. But maybe it's just the lighting.

Demick

No, I have seen two styles or that one is a replacement one. The one in the BA pic is from a OEM unmolested unit.

I checked the outer screws size and its a 12mmx1.00thread pitch. Very fine threads

I checked the outer screws size and its a 12mmx1.00thread pitch. Very fine threads

so, where are we with this project?

Do we have a drawing yet?

Do we know the hardness of the material in question?

I talked to the berilium guy today and he can do it, but its all talk till he sees a drawing...better than my hand scetch

Rich

Do we have a drawing yet?

Do we know the hardness of the material in question?

I talked to the berilium guy today and he can do it, but its all talk till he sees a drawing...better than my hand scetch

Rich

| QUOTE (r_towle @ Jan 16 2006, 12:20 PM) |

| Now, how do we verify the actual material... Correct me if I am wrong...the patent documents do not declare the material??? Does anyone have any contacts at Bosch we could ask for a clear answer?? |

I more than likely can do the material composition test of the diaphram if it is still needed.

Where I work, we have a Niton Alloy Analyzer, which is a non-destructive, hand-held tester for alloy materials. It'll actually tell you the chemical composition of any alloy it tests.

Let me know.

Do you need sample diaphragms? I have a fair number of cracked ones. One should not assume the material never changed.

Great RustyWa,

I'll drop one off to you (OEM) whenever and pickup the Janbo too. Let me know....other than today as I am jetlagged out from coming back gistern.

Geoff

I'll drop one off to you (OEM) whenever and pickup the Janbo too. Let me know....other than today as I am jetlagged out from coming back gistern.

Geoff

Great. Even a scrap piece about the size of a quarter will work.

Anytime after 5:30pm during the week is good for me. The weekends are pretty open as well. This week I have Friday off as well.

If it would work out easier, during the day, I can get everything together and my wife will be home.

Of course, I have no problem driving up to you this Friday or the weekend.

I also have that flywheel of yours that I never used.

Anytime after 5:30pm during the week is good for me. The weekends are pretty open as well. This week I have Friday off as well.

If it would work out easier, during the day, I can get everything together and my wife will be home.

Of course, I have no problem driving up to you this Friday or the weekend.

I also have that flywheel of yours that I never used.

Ok, did the marterial analysis on the OEM diaphram this morning using a Niton XL-II 800 handheld alloy analyzer.

I made three different scans of the sample piece I got from Geoff. The readings were as follows:

#1 - 99.78% Cu

#2 - 99.20% Cu

#3 - 99.39% Cu

No berillium. Supposedly anything between 98%-100% copper is considered pure.

The remainder of the 100% reading was a spattering of Al, Si Br, Phos Brz.

I made three different scans of the sample piece I got from Geoff. The readings were as follows:

#1 - 99.78% Cu

#2 - 99.20% Cu

#3 - 99.39% Cu

No berillium. Supposedly anything between 98%-100% copper is considered pure.

The remainder of the 100% reading was a spattering of Al, Si Br, Phos Brz.

| QUOTE (Jenny @ Jan 12 2006, 09:00 AM) |

| bugger... the picture didn't take. |

So did I !

So,

its copper?

Is there a specific hardness that needs to be found?

Rich

its copper?

Is there a specific hardness that needs to be found?

Rich

| QUOTE (r_towle @ Feb 27 2006, 03:05 PM) |

| So, its copper? Is there a specific hardness that needs to be found? Rich |

as I posted on his other thread.....

**********************

I still say it's BeCu......

Add your % findings to the % composition for second type.....

| QUOTE |

| Beryllium Copper -------------------------------------------------------------------------------- Overview Copper beryllium alloys are used for their high strength and good electrical and thermal conductivities. There are two groups of copper beryllium alloys, high strength alloys and high conductivity alloys. The wrought high strength alloys contain 1.6 to 2.0% beryllium and approximately 0.3% cobalt. The cast, high-strength alloys have beryllium concentrations up to 2.7%. The high conductivity alloys contain 0.2-0.7% beryllium and higher amounts of nickel and cobalt. These alloys are used in applications such as electronic connector contacts, electrical equipment such as switch and relay blades, control bearings, housings for magnetic sensing devices, non sparking applications, small springs, high speed plastic molds and resistance welding systems. Cast beryllium coppers are frequently used for plastic injection molds. The cast materials have high fluidity and can reproduce fine details in master patterns. Their high conductivity enables high production speed, while their good corrosion and oxidation resistance promotes long die life. The UNS designations for the wrought alloys are C17200 through C17400 and the cast alloys are C82000 through C82800. The high strength of the copper beryllium alloys is attained by age hardening or precipitation hardening. The age or precipitation hardening results from the precipitation of a beryllium containing phase from a supersaturated solid solution of mostly pure copper. The precipitation occurs during the slow cooling of the alloys because the solubility of beryllium in alpha copper decreases with decreasing temperature. Typically the alloys are rapidly cooled from the annealing treatment, so the beryllium remains in solid solution with the copper. Then the alloy is given a precipitation or age hardening treatment for an hour or more at a temperature between 200 and 460 C. Upon tempering, the beryllium containing phases, called beryllides, precipitate out of solution. |

More BeCu info as well as pure copper and other copper alloys

ok,

But, could we find a Copper alloy that has the same hardness charateristics as this diaphram? Obvious reason is that Mueller could make it in his garage...versus making it in a special room etc...

Does copper come in different hardness's?

Rich

But, could we find a Copper alloy that has the same hardness charateristics as this diaphram? Obvious reason is that Mueller could make it in his garage...versus making it in a special room etc...

Does copper come in different hardness's?

Rich

I agree that pure copper seems like a very odd choice. Work hardening would seem to be a real problem with pure copper. BeCu would be a much better choice. I don't understand it, but I can't argue with the analyzer results.....

Demick

Demick

| QUOTE (RustyWa @ Feb 27 2006, 12:46 PM) |

| Ok, did the marterial analysis on the OEM diaphram this morning using a Niton XL-II 800 handheld alloy analyzer. I made three different scans of the sample piece I got from Geoff. The readings were as follows: #1 - 99.78% Cu #2 - 99.20% Cu #3 - 99.39% Cu No berillium. Supposedly anything between 98%-100% copper is considered pure. The remainder of the 100% reading was a spattering of Al, Si Br, Phos Brz. |

unless I mistaken, that analyzer will not pickup Be according to the spec sheet...........(unless tested in a vacuum)

| QUOTE (Mueller @ Feb 27 2006, 04:35 PM) |

| unless I mistaken, that analyzer will not pickup Be according to the spec sheet...........(unless tested in a vacuum) |

..good catch Mike.

Sorry for a very delayed response from me on this with relation to the drawing for the diaphragm. I have been extremely busy lately and didn't get to spend much time on it.

Jeff B. and I did have some offline discussions during this time. Originally, I had planned on designing the boss on the diaphragm so that it would attach to the diaphragm with a threaded nut. So I was going to try and source an appropriate sized nut to do this. But Jeff suggested that we just replicate the original design rather than trying for the nut approach. I'm fine with that.

But the diaphragm that Jeff sent me is a good one and he doesn't want it destroyed. And in the assembled state, it is very difficult for me to tell which parts are which in the pressed-together state. Here is what I wrote to Jeff regarding this:

With the idea of replicating the original, it is very difficult for me to tell how it was assembled without cutting one apart. There are 4 'steps' to the center boss where the retainer is installed. It is difficult for me to tell which part is what, and if the retainer is simply a retaining ring that has been pressed on, or if it is a part that is highly deformed when pressed on (as in, the retainer starts out as a ring, but ends up with a step in it).

Anyway, take a look at the images I have attached. This is one way it could have gone together. It involves four parts: the diaphragm, the boss, a washer, and the retainer. In this case, the retainer is just pressed into place (not deformed).

Here is the exploded view I sent him:

Jeff B. and I did have some offline discussions during this time. Originally, I had planned on designing the boss on the diaphragm so that it would attach to the diaphragm with a threaded nut. So I was going to try and source an appropriate sized nut to do this. But Jeff suggested that we just replicate the original design rather than trying for the nut approach. I'm fine with that.

But the diaphragm that Jeff sent me is a good one and he doesn't want it destroyed. And in the assembled state, it is very difficult for me to tell which parts are which in the pressed-together state. Here is what I wrote to Jeff regarding this:

With the idea of replicating the original, it is very difficult for me to tell how it was assembled without cutting one apart. There are 4 'steps' to the center boss where the retainer is installed. It is difficult for me to tell which part is what, and if the retainer is simply a retaining ring that has been pressed on, or if it is a part that is highly deformed when pressed on (as in, the retainer starts out as a ring, but ends up with a step in it).

Anyway, take a look at the images I have attached. This is one way it could have gone together. It involves four parts: the diaphragm, the boss, a washer, and the retainer. In this case, the retainer is just pressed into place (not deformed).

Here is the exploded view I sent him:

And below is the assembled version.

Maybe Geoff or Dave can send me a bad diaphragm (OK if it is already cut in half). That way, I will be able to replicate exactly the design the factory had for this.

Demick

Maybe Geoff or Dave can send me a bad diaphragm (OK if it is already cut in half). That way, I will be able to replicate exactly the design the factory had for this.

Demick

It is not a 3 piece unit but two pieces. The ring is held in place by the collar being mashed onto it at the step shown by the red arrow.

I can send you the other half piece I have sitting here on my desk. Send your address to me.

I can send you the other half piece I have sitting here on my desk. Send your address to me.

A bump

I still have a company that will make the berillium part.

We need metal properties, and measurements on any drawings...

Rich

I still have a company that will make the berillium part.

We need metal properties, and measurements on any drawings...

Rich

yeah, what happened to this project? I keep getting requests for rebuild MPS's and I have very few good oem diaphrams to use.

RustyWA??? any further news? besides you selling your car...

RustyWA??? any further news? besides you selling your car...

Aw shoot. I had forgotten about this. I finished the drawings and sent them to Jeff Bowlsby, but this was during the week(s) when 914club was down and I never posted it here.

Anyway, I modeled two different diaphragms. One with the larger pleats, and one with the smaller pleats. Both were sent to me by Jeff. I don't know in what MPS's the different versions were used.

I believe that the material used on the two diaphragms may be different. One of the clues to this was that the diaphragm with small pleats was highly discolored, and the one with large pleats was nice and shiny with no sign of corrosion or discoloration. For now, the drawings call out quarter hard beryllium copper, but that can change at any time. I think the initial purpose of this exercise was just to define the shape of the diaphragm for quoting purposes.

PDF's of the two drawings are available here:

MPS diaphragm, Large Pleats

MPS diaphragm, Small Pleats

Demick

Anyway, I modeled two different diaphragms. One with the larger pleats, and one with the smaller pleats. Both were sent to me by Jeff. I don't know in what MPS's the different versions were used.

I believe that the material used on the two diaphragms may be different. One of the clues to this was that the diaphragm with small pleats was highly discolored, and the one with large pleats was nice and shiny with no sign of corrosion or discoloration. For now, the drawings call out quarter hard beryllium copper, but that can change at any time. I think the initial purpose of this exercise was just to define the shape of the diaphragm for quoting purposes.

PDF's of the two drawings are available here:

MPS diaphragm, Large Pleats

MPS diaphragm, Small Pleats

Demick

I think the large pleat is like the OEM design, the small pleats is the Brett Ins type.

Let's just break into Brett Inst. and steal their stash of diaphrams!

Where is Miles when you need a good plan!

oh dear!

I don't have time to draw one up... find the old one, and change these variables:

Brad=Diaphram

Cops=Employees

Aaron&Matt=Whomever is close

See you at Uncle Jiggly's

M

I have a little bit of experience forming beryllium Copper (33 yrs) I could make these, but the form tools would run about $2000 for each of the two designs.

I commend the work you gents are doing on this. If/when it comes down to ponying up for the first batch to cover costs I'll donate $50.

Does anyone have the value curves for these? I am supprised no one has hidden a solid state MPS in the old unit that would mimic the correct signals for the given pressures. Has someon mentioned this and I missed it?

I could do it if I had the values that I needed. I may need to set up a circuit to compensate for certain variables, but it seems very doable and would keep your system looking/performing stock.

Anyone wanna work with me on this.....not like we are all in a hurry

I could do it if I had the values that I needed. I may need to set up a circuit to compensate for certain variables, but it seems very doable and would keep your system looking/performing stock.

Anyone wanna work with me on this.....not like we are all in a hurry

Here's a site to look at....

http://news.thomasnet.com/fullstory/453621/2399

We need a vacuum sensor not a pressure sensor, I have no time to delve into this.

http://news.thomasnet.com/fullstory/453621/2399

We need a vacuum sensor not a pressure sensor, I have no time to delve into this.

That is what I am reffering to in part. My MJLJ has a vaccume MPS that is the size of a quater. I was just looking over the brian schematics and it looks failrly straight forward. I just need the values that I should be shootinf for, or I will take a much longer time and rig up test connectors to a running car, yadda, yadda.

I am not saying I know it all, far from it. I'm just saying that I have not seen a reason not to consider this line of thinking.

I am not saying I know it all, far from it. I'm just saying that I have not seen a reason not to consider this line of thinking.

I started to look into a just haven't as I have been outta the country workin...

Its all yours baby!

Its all yours baby!

Dr. Evil Sir...

The values are on Brad Anders fine site. The MPS converts intake manifold vacuum, or rather the micro-dimensional displacement distance on a diaphragm subjected to the change in vacuum pressure...to an electical inductance value. Can you do that?

The values are on Brad Anders fine site. The MPS converts intake manifold vacuum, or rather the micro-dimensional displacement distance on a diaphragm subjected to the change in vacuum pressure...to an electical inductance value. Can you do that?

Maybe, havent tried it yet, but I am willing to give it a try

i guess that we never got a clear answer about the metal properties...

Hardness and alloy...

If I get that..and take these drawings, at least I can get a price.

Rich

Hardness and alloy...

If I get that..and take these drawings, at least I can get a price.

Rich

Maybe, havent tried it yet, but I am willing to give it a try

I looked on thomas.net and alibabi (SP) and I found several screw in ones that measure vacuum, and produce elec....

One of the companies said they would make it any way that was needed....

So, search there...

I could possibly help provide readings...

We can talk about that...but I think I could rig up an inline system to the car to take readings and plop it all on a computer so we can map it out...

Rich

I am not saying I know it all, far from it. I'm just saying that I have not seen a reason not to consider this line of thinking.

There are a bunch of us who have thought about this. Like you point out, a pressure sensor that outputs a porportional voltage (or resistance) is easy to get. A standard MAP sensor is cheap and readily available that would do this (Megasquirt uses a MAP sensor like this).

Unfortunately, to mimmic the MPS, you would need to take this signal and create an inductance value based on the amount of vacuum. A hefty inductance value at that (0 - 1.5H). I know of no voltage controlled variable inductor - especially at that kind of value. So this is where I get stuck. Not a simple problem.

The other approach is not to mimmic the MPS exactly, but to understand how the ECU interprets this inductance, and create a circuit that does not output an inductance, but rather another type of signal that the MPS would be able to correctly interpret. But this goes way beyond my electrical capabilities.

Demick

Demick, you hit it right on the head. I figured a veriable inductance circuit is gonna be the bain of this whole thing. I figured if it were easy one of you all would have already done it. I just wanted some input and values and such so I can start to ponder about a solution as well. I definetly wish to share what I find with the group. Like Geoff, I am not out to make a fortune on these. I want a solution so I can keep all of my friends onthe road......looking like a stud for solving this problem wouldn't hurt  But, we shall see. I have 15 years electronics experience (before med school) and am a wiz at figuring out circuits. I bet Jeff Keyzer and Tony Long could help a lot on this problem as they are EEs.

But, we shall see. I have 15 years electronics experience (before med school) and am a wiz at figuring out circuits. I bet Jeff Keyzer and Tony Long could help a lot on this problem as they are EEs.

Just dont expect a fast solution....like Geoff, I too have other obligations

Just dont expect a fast solution....like Geoff, I too have other obligations

email Brad Anders too Dr Evil as he has studied and understands Djet like no one else. He is also a Electrical Eng working for Intel. He mostly posts on PP or Rennlist as I think there is too much OT chatter for him here.

Jeff Keyser and I have spoken about this at length.

The variable inductor in the MPS basically takes a squareish wave in (from the trigger points), and puts a squareish wave out, modified by the manifold pressure and the air temp (which gets fed back in by the ECU). This square wave is then furthur modified by the ECU, and eventually becomes the pulsewidth train for the injectors.

So, no variable inductor is really required. Instead, you use the pulse capture module on one of the many microcontrollers, read a solid-state MAP sensor, read a temp sensor, then calculate the waveform out in a very similar manner to the way normal fuel ECUs do. Generating the waveform from there is easy. 90% of this could happen in software.

However, the marginal cost of building and programming and testing this thing would exceed that of a Megasquirt kit, which solves the problem, as well.

If you were willing to eat all of the R&D costs, the final unit would likely be simpler and cheaper than a Megasquirt, partly because you could use a simpler processor, and because you'd not need a lot of parts the MS uses, like injector drivers (the D-Jet ECU would do that). Indeed, I think all you'd need is a power supply (one $5 IC, a few resistors and caps), a microcontroller (under $10 in single unit quantities), a MAP sensor (about $25), and a bit of signal conditioning (more resistors and caps, about $1). The whole thing could easily be made to fit into a MPS housing with the guts removed. You'd need to do some rewiring, as I don't think the MPS gets a solid +12 or ground connection (you'd need both).

There would probably still be some tuning limitations set by the stock ECU, so while you'd certainly be able to use this electronic MPS for any engine from a stock 1.7 up to a pretty wild 2056, I'd bet you'd run into problems with, say, a 2316 or so. Hard to say for sure.

A Megasquirt would be cheaper, far easier, and would allow more tuning flexibility.

The variable inductor in the MPS basically takes a squareish wave in (from the trigger points), and puts a squareish wave out, modified by the manifold pressure and the air temp (which gets fed back in by the ECU). This square wave is then furthur modified by the ECU, and eventually becomes the pulsewidth train for the injectors.

So, no variable inductor is really required. Instead, you use the pulse capture module on one of the many microcontrollers, read a solid-state MAP sensor, read a temp sensor, then calculate the waveform out in a very similar manner to the way normal fuel ECUs do. Generating the waveform from there is easy. 90% of this could happen in software.

However, the marginal cost of building and programming and testing this thing would exceed that of a Megasquirt kit, which solves the problem, as well.

If you were willing to eat all of the R&D costs, the final unit would likely be simpler and cheaper than a Megasquirt, partly because you could use a simpler processor, and because you'd not need a lot of parts the MS uses, like injector drivers (the D-Jet ECU would do that). Indeed, I think all you'd need is a power supply (one $5 IC, a few resistors and caps), a microcontroller (under $10 in single unit quantities), a MAP sensor (about $25), and a bit of signal conditioning (more resistors and caps, about $1). The whole thing could easily be made to fit into a MPS housing with the guts removed. You'd need to do some rewiring, as I don't think the MPS gets a solid +12 or ground connection (you'd need both).

There would probably still be some tuning limitations set by the stock ECU, so while you'd certainly be able to use this electronic MPS for any engine from a stock 1.7 up to a pretty wild 2056, I'd bet you'd run into problems with, say, a 2316 or so. Hard to say for sure.

A Megasquirt would be cheaper, far easier, and would allow more tuning flexibility.

I think the fundamental question here is, are you trying to come up with an MPS replacement, or an MPS and ECU replacement?

An MPS replacement would retain the stock ECU, and be a simple swap out of the MPS for a solid state one. Since the MPS is the least reliable, most expensive, and hard to get item in the fuel injection system, I think this is worthwhile to try and do.

However, an MPS and ECU replacement (which James is talking about above), seems pretty pointless to me. As long as you are essentially replacing the whole FI control system, you might as well just start with Megasquirt or one of the other aftermarket FI systems and go from there. But the end result needs to be a plug-and-play system. And the hurdles for making a plug-and-play system are pretty much the same for a 914 specific custom FI replacement, Megasquirt, or any other aftermarket FI system.

Demick

An MPS replacement would retain the stock ECU, and be a simple swap out of the MPS for a solid state one. Since the MPS is the least reliable, most expensive, and hard to get item in the fuel injection system, I think this is worthwhile to try and do.

However, an MPS and ECU replacement (which James is talking about above), seems pretty pointless to me. As long as you are essentially replacing the whole FI control system, you might as well just start with Megasquirt or one of the other aftermarket FI systems and go from there. But the end result needs to be a plug-and-play system. And the hurdles for making a plug-and-play system are pretty much the same for a 914 specific custom FI replacement, Megasquirt, or any other aftermarket FI system.

Demick

I think coming up with new MPS diaphrams is a good thing, since this really is a 100% plug and play solution, and would suit those who want a 100% stock car.

For those wanting a solid-state replacement, however, you only have two options. Use a solid-state MAP sensor and some amount of analog electronics to emulate the variable inductor. This would be pretty difficult to design, and I'd expect the parts count to be high, so the device would be fairly expensive to make. The other option is to use a microcontroller to do the job digitally, at which point Demick is right in saying you might as well just use Megasquirt, et al.

For a full stock appearance, it wouldn't be at all difficult to fit a Megasquirt board in a stock ECU housing, and fit a solid state MAP sensor into an MPS. This could use a stock FI harness, and would be indistinguishable from a stock setup without disassembling the ECU and the MPS.

For those wanting a solid-state replacement, however, you only have two options. Use a solid-state MAP sensor and some amount of analog electronics to emulate the variable inductor. This would be pretty difficult to design, and I'd expect the parts count to be high, so the device would be fairly expensive to make. The other option is to use a microcontroller to do the job digitally, at which point Demick is right in saying you might as well just use Megasquirt, et al.

For a full stock appearance, it wouldn't be at all difficult to fit a Megasquirt board in a stock ECU housing, and fit a solid state MAP sensor into an MPS. This could use a stock FI harness, and would be indistinguishable from a stock setup without disassembling the ECU and the MPS.

Interesting concept. It could more easily do that for sure, but then it would be easy

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please click here.