Wes V

Oct 4 2008, 07:07 PM

I think I've come up with a totaly new way to hook up 911 parking brakes. It involves making up longer hybrid cables.

It's not complex, doesn't cost tons, and is about as straight forward as possible.

It functions exactly as intended in the 911.

Here is a teaser photo;

Here is a link to my write-up on how I did it (it's a preliminary write-up).

hybrid cablesWes

(can somebody please find me the photo that I've seen on this site where somebody used a cable end block at the parking brake lever that had set screws)

okieflyr

Oct 4 2008, 07:55 PM

Sweeeeet!

![popcorn[1].gif](http://www.914world.com/bbs2/style_emoticons/default/popcorn[1].gif)

Wilhelm

Oct 4 2008, 09:53 PM

Nice write up.

What are your ideas for the parking brake handle end of the cable?

Have you run across a source of cable ends and sheathing do your own custom cables?

Are new ends generally crimped on or silver soldered?

LarryR

Oct 4 2008, 10:09 PM

Very nice! I am getting ready to to the 911 brake swap with 911 ebrake and have been thinking a lot about the cables.

Larry

Wilhelm

Oct 4 2008, 10:38 PM

QUOTE(Wilhelm @ Oct 4 2008, 08:53 PM)

Nice write up.

What are your ideas for the parking brake handle end of the cable?

Have you run across a source of cable ends and sheathing do your own custom cables?

Are new ends generally crimped on or silver soldered?

So I'll reply to myself!!!!!!

After some web searching, looking especially at "dune buggy" companies, I'm finding all sorts of bits to shorten and put custom ends on cable. If possible I would like to make seamless cables brake-to-handle with the appropriate ends for my specific application.

PRS914-6

Oct 4 2008, 11:17 PM

Nice write up. Most of us have thought of the idea but didn't care for the angle that the cable attaches to the e-brake because of the shape of the arm. You can't get a straight pull which has a tendency to pull the linkage.

The advantage of the bellcrank version is that you get to use the OEM cables and get a straight pull on the e-brake mechanism by offsetting the arm. Here is a pic

Click to view attachment

Larry.Hubby

Oct 5 2008, 03:49 AM

Clever and resourceful, Wes. Looks good!

Larry

PRS914-6

Oct 5 2008, 08:50 AM

Another thought on your idea........I don't have an arm here to look at but is there enough room to cut the arm (notch it) and weld a tube in its place with a straight shot to the mechanism? Also, I'm not sure but I'll look the next time my car is on the rack but there might be header interference with the cable out away from the arm...it's very close on a 6. Might need a tight 90 deg there.

You can draw a sketch of exactly what you want and send it to Terry cable and they will manufacture the cable perfectly as you like.

Wes V

Oct 5 2008, 11:27 AM

The issue with the bell-crank solution is that it only "pulls" on one of the speaders. I'm calling it an "issue" and not a "problem" due to the fact that several people have had good results with doing it this way.

As for anchorage of the cable at the parking brake lever, I'm going to work up something using set-screws. It's kind of a no-brainer and I'm not worried about it.

All of the end fittings I've seen in automotive installations are swedged (crimped) on.

Terrycable will do custom cables (according to Otto's in Santa Monica), but they are pricey.

Wes

Wilhelm

Oct 5 2008, 11:52 AM

QUOTE(Wes V @ Oct 5 2008, 09:27 AM)

The issue with the bell-crank solution is that it only "pulls" on one of the speaders. I'm calling it an "issue" and not a "problem" due to the fact that several people have had good results with doing it this way.

As for anchorage of the cable at the parking brake lever, I'm going to work up something using set-screws. It's kind of a no-brainer and I'm not worried about it.

All of the end fittings I've seen in automotive installations are swedged (crimped) on.

Terrycable will do custom cables (according to Otto's in Santa Monica), but they are pricey.

Wes

The 928,944, 924 mechanism requires only a pull, not compression of the spreader, and thus may be more suitable for the bellcrank crowd. The 928 shoes are the same size as the 944 and 911 and instead of having rivets for the spreaders to push on, have notches for the mechanism to lever on much like the brake shoes of american cars. The spreader is part 20 in this pic.

Click to view attachment

jj83118

Oct 5 2008, 03:13 PM

I was going to post my 911 e-brake cable solution, but I didn't get around to it until now.

I used two clutch cables and modified stock e-brake cable housings. I cut the pedal-end of the clutch cable off and shortened the threaded end a bit. Then I used a cut-off wheel to carefully remove the slotted ends of the stock e-brake cables off. If you make two long cuts 180 degrees apart, you can pry the crimped ends off for use later.

I used a short section of tubing that allowed a tight fit on the stock cable housings outer diameter and spot welded a short section of smaller tubing inside as a stop. This part plays double duty as a mount (all you need is to drill and tap a hole in the trailing arm).

I cut the housings to length first, then slid the clutch cables in to find the right length. After that, it is just a simple matter of re-crimping the ends on the cables and welding them (weld only on the crimped part into the cable).

I hope this all makes sense...I am including photos that better describe the process.

Click to view attachment

jj83118

Oct 5 2008, 03:16 PM

Another shot from the inside.

jj83118

Oct 5 2008, 03:17 PM

Welded cable end.

jj83118

Oct 5 2008, 03:19 PM

A complete cable (still need to shorten the threaded end).

Wilhelm

Oct 5 2008, 04:50 PM

QUOTE(jj83118 @ Oct 5 2008, 01:17 PM)

Welded cable end.

So when you cut this cable end, did you essentially split the tube and pull the old cable out? I take it you welded the cuts back together to remake a tube and then crimped this tube shut. Is Crimping always best? Does silver soldering the end onto the cable embrittle the end of the cable. I seem to remember 30 years ago a well driller reattaching his drillbit ends on 1" steel cable by brazing.

sixnotfour

Oct 5 2008, 04:54 PM

QUOTE

Does silver soldering the end onto the cable embrittle the end of the cable. I seem to remember 30 years ago a well driller reattaching his drillbit ends on 1" steel cable by brazing.

silver solder the way to go but crimping is way more effective.

never have tried the mig weld.

Wes V

Oct 5 2008, 06:17 PM

QUOTE(jj83118 @ Oct 5 2008, 02:17 PM)

Welded cable end.

I like this!

I never thought it would be possible to remove and replace the end fitting.

What type of welder did you use? (mig or tig)

Wes

(dang photo isn't coming up)

ClayPerrine

Oct 5 2008, 07:06 PM

This thread made me want to post this now. The problem I see (from experience) is the way the cable is routed in the other thread, you are going to melt it against the heat exchanger/header. It is just too close!!!

I came up with a different way to do the 911 park brake, using the stock 914 park brake cables.

First, buy some 1" conduit, and a conduit bender. Then bend the conduit until you have a 90 to 100 degree bend with a nice, gentle radius.

Weld the washer from the inboard end of the 911 park brake setup onto the end of the bent conduit. Drill a 1/8 inch hole in the outside of the tube, right at the end where the washer is welded. On the other end, cut 3 slots parallel with the end of the tube 1/16 inch from the end.

Click to view attachmentClick to view attachmentClick to view attachmentTake the 911 park brake cables that you got with the brakes, and cut them off. Pull out the inside, and make sure that you leave the cable long enough that it will reach the end of the tube when the threaded end is pushed through the hole in the washer. Braise up the cable end that was cut to keep it from fraying.

Click to view attachment You can see the cutoff 911 park brake cable and the tubing in the background.

Then go to the hardware store and buy a couple of barrel nuts used for lawn mower cables. Measure the amount the rear end of the 914 park brake cable sticks out when it is disconnected from the handle and pulled all the way rearward. Drill out the clevis on the end of the 914 park brake cable so the barrel nut will go through it.

Put the barrel nut into the clevis on the end of the 914 park brake cable. Slip the braised end of the 911 park brake cable into the barrel nut. Tighten the barrel nut, then grind the barrel nut flush with the side of the clevis. Trim off the excess cable until you can make a straight cable out of the two joined cables.

Click to view attachmentClick to view attachmentPut the now extended 914 park brake cable into the tube, and using the 1.8 inch hole in the side, push it through until you can pull the end out the center of the washer.

Put an E clip into the slots cut in the tube to hold it to the 914 park brake cable. Hook it up to the 911 park brakes on the back, and the handle on the front. Make sure the adjustment nuts are all the way back when you put the cables into the chassis on the handle ends.

Take the end of the tube and support it where the original park brake cable end goes using a 6x.10 bolt, 2 6mm fender washers, and a padded cable clamp. This allows the cable to flex to the side when you pull the park brake.

Click to view attachmentClick to view attachmentYou can see from the pictures that the cables never come near the heat exchangers, and the park brake works great on my car!

Adjustment:

Adjust the shoes per the 911 service manual. When your shoes are adjusted correctly, then use the adjustment nuts on the cables to adjust the handle height when the brake is pulled.

I can take additional pictures of the brake setup, or you can see it in person at the Rocket City Ramble. Bring your Cameras!

Wes V

Oct 5 2008, 08:09 PM

Clay;

The fact that what I did would place the sheathing close to the heat exchanger is a very valid consern!! My car is an on-going project and I don't know if it will be a problem at a latter date or not. (I'm planning an engine swap)

Most of the time that I post stuff, it's to get an idea out there. It seems to have worked due to a bunch of methods being brought up.

(I did think of making up the length of 1/2" stainless steel tube with a 90 degree bend, however the bender I have would have put too tight of a radius bend on it for what I was comfortable with)

Wes Vann

ClayPerrine

Oct 5 2008, 08:42 PM

QUOTE(Wes V @ Oct 5 2008, 09:09 PM)

Clay;

I'd have prefered that you just post this after the string I did. I'm not going to be offended.

The fact that what I did would place the sheathing close to the heat exchanger is a very valid consern!! My car is an on-going project and I don't know if it will be a problem at a latter date or not. (I'm planning an engine swap)

Most of the time that I post stuff, it's to get an idea out there. It seems to have worked due to a bunch of methods being brought up.

(I did think of making up the length of 1/2" stainless steel tube with a 90 degree bend, however the bender I have would have put too tight of a radius bend on it for what I was comfortable with)

Wes Vann

Ok.. I didn't want to hijack your thread. I can merge them for us.

My method is cheap, probably around 50 bucks all told.

I had a 911 park brake in my car since I got it running 3 years ago. I used custom cables at first, and I melted one on the heat exchanger. That is why I came up with this method. You, being a machinist, could probably do it better, but it works.

I know from looking at the cable radius yours is going to contact the heat exchanger/headers.

I need a stop for mine like you put in.

jj83118

Oct 5 2008, 09:32 PM

I welded the crimped ends back on with a MIG welder and I did not weld all the way to the end. You don't want to weaken the cable.

I don't think I would attempt to silver solder or braze the ends as you will be fighting capillary action as the solder wicks its way up the cable.

I'll have to check header clearance once the engine is put back in my car (it's been out for quite some time now). If there is interference, I might be able to put an Adel clamp on the cable and attach it to the trailing arm.

andys

Oct 6 2008, 10:57 AM

QUOTE(PRS914-6 @ Oct 5 2008, 07:50 AM)

Another thought on your idea........I don't have an arm here to look at but is there enough room to cut the arm (notch it) and weld a tube in its place with a straight shot to the mechanism? Also, I'm not sure but I'll look the next time my car is on the rack but there might be header interference with the cable out away from the arm...it's very close on a 6. Might need a tight 90 deg there.

You can draw a sketch of exactly what you want and send it to Terry cable and they will manufacture the cable perfectly as you like.

Wes,

Very nice write-up!

For you bell crank types, Wes came up with a very clever solution which employs a compound bell crank that provides opposing actions. He claims it's a bit too complex but, I disagree and think it's a unique solution and it allows the use of the stock e-brake cables. Wes, can you post some photos of this?

The one funamental problem with the 911 e-brake is getting a nice straight shot at the actuator. All the solutions place the cable at a slight angle; I don't know for sure how much of a real issue this is (perhaps none) but it "seems" less than ideal. Short of modifying the trailing arm, you're pretty much stuck with this as is.

Wilhelm, do you have a close photo of that 928 brake shoe spreader? Seems like it would simplify things quite a bit.

Andys

Richard Casto

Oct 6 2008, 12:49 PM

Wes,

Thanks for showing how you did this. I am still trying to decide how I am going to do this on my end.

Richard

Richard Casto

Oct 6 2008, 12:55 PM

QUOTE(Wilhelm @ Oct 5 2008, 01:52 PM)

The 928,944, 924 mechanism requires only a pull, not compression of the spreader, and thus may be more suitable for the bellcrank crowd. The 928 shoes are the same size as the 944 and 911 and instead of having rivets for the spreaders to push on, have notches for the mechanism to lever on much like the brake shoes of american cars. The spreader is part 20 in this pic.

Click to view attachmentI like the idea of the bellcrank approach because I would prefer to not make custom cables and would like to do this with off the shelf parts as much as possible. But I don't like how this does not compress the 911 spreader as it is supposed to. But the 928/944/924 pull mechanism sounds really interesting. Has anyone tried this yet?

Richard

Wes V

Oct 6 2008, 01:12 PM

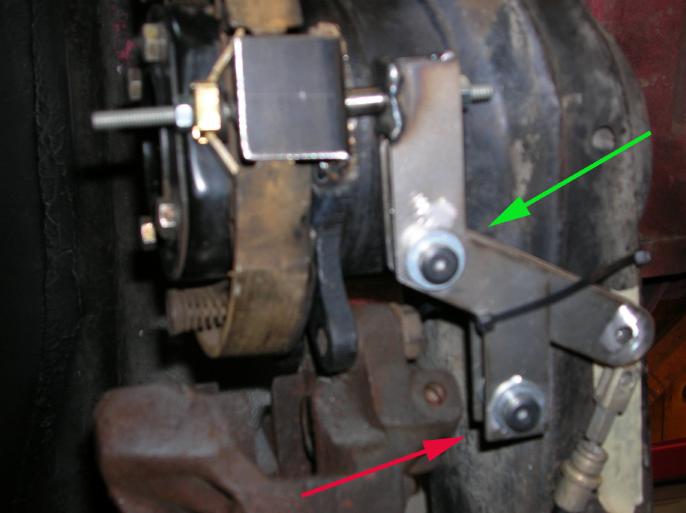

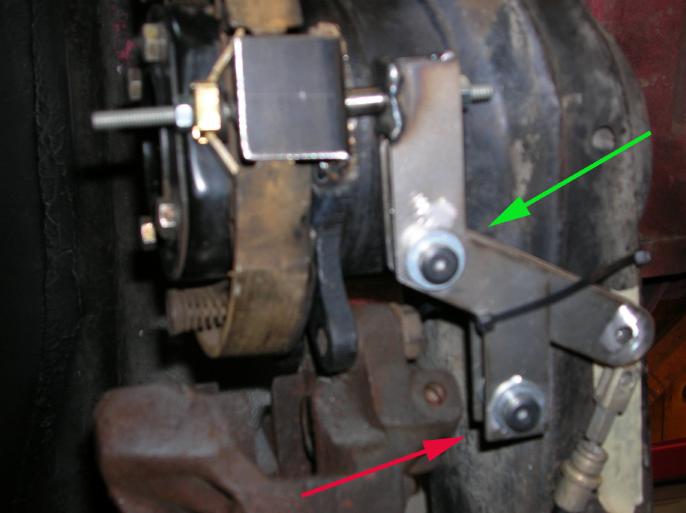

This is what AndyS is talking about when he comments on the "lever" design I did. He knew about it due to my sending him photos for discussion.

Prior to working up the method in my write-up, I did a couple designs that involved a lever action, which would still work the "push and pull" on the 911 spreaders.

I guess it's worth posting. (sorry about the first photo not being focused very well)

(Andy also voiced consern on the "cable method" being too close to the exhaust)

In order to figure out how it works you first off have to know that the allen head bolts are shoulder bolts and work as pivot points.

Then you have to know that the green arrow points to a "floating" pivot point. It isn't attached to anything other that the arms and can move in space.

The last thing is that the pivot point pointed to by the red arrow would be attached to the trailing arm. It's a "fixed" pivot point.

There is a short section of stainless steel tube that pushed on one of the spreaders, while a 1/4" thread rod pulls on the other.

Ya, it would work, but I just thought there had to be a less complex way to do it.

That black tie-wrap is just holding it in place for the photo.

The following photos are showing the linkage on the garage floor, just to make it more clear.

And the following photo shows the two arms.

The one on the right fits inside the one on the left.

Both arms have a "bearing plate" on the end. The one on the left is what the length of tube bears on and also has a hole that the threaded rod can pass through. The one on the right is what the nut on the threaded rod bears on.

Discuss away!!

Wes Vann

Richard Casto

Oct 6 2008, 01:47 PM

Wes,

Thats pretty cool. Basically its just like the regular bellcrank solution, but that the pivot point for the bellcrank is not static. So the force on a normal bellcrank pivot would be against the arm (with pivot bolted or welded to the arm). But in this solution the bellcrank pivot is free to move, so that force is now applied to the other half of the spreader. In a way its much like a cable solution because the cable is free to move a bit as well.

I like it, but it is more parts, more fabrication and more things to go wrong. After looking at your solution I tried to sketch out some other ways to do it, but they basically result in something that is a bellcrank with a floating pivot and so far I can't think of something that is simplier than what you have.

One thing I haven't seen anyone try to re-engineer is the 911 spreaders. A drop in replacement for those parts that only requires you to pull would be interesting. I still wonder if the 924/944/928 spreader mentioned earlier will work or not.

Richard

Wes V

Oct 6 2008, 02:03 PM

Richard;

In light of the fact you can figure out how it works, you have got to be an Engineer!! It's kind of a mind trip because you have to thing about things floating in space and balancing forces.

I really don't think that there is a better "balanced bell crank" solution due to the physical restraints.

My first attempt was better, but wouldn't clear everything as I hoped.

You really have to build one to see how it clears stuff.

The 924 solution is interesting, but without having parts in front of you it's hard to say how possible it would be.

Here are things that come to mind;

You would have to swap the brake shoes and spreaders at a minimum.

Will the shoes fit on the 911 backing plate?

Are the shoes the same size. Or viewed another way, is the drum diameter the same?

You would have to modify the 911 backing plate to clear the spreader.

If it's possible to swap the complete assembly, the attachment bolt spacing would be wrong (larger bearings on latter cars). It may just be a matter of opening up the bolt holes.

I REALLY wish that I had a friend at a Porsche junk yard!

Wes

Richard Casto

Oct 6 2008, 03:43 PM

I am an Electrical Engineer by training, but I still remember my first year basic engineering classes (free body diagrams, etc.) that all the engineers had to take.

You are right on all of your points regarding the 924 solution. Someone just needs to assemble the parts and see what can be done. If someone wants to send me the 924/944/928 parts, I will give it a try and report back!

Wes V

Oct 6 2008, 05:15 PM

QUOTE(Richard Casto @ Oct 6 2008, 02:43 PM)

If someone wants to send me the 924/944/928 parts, I will give it a try and report back!

Dang, I was wishing the same thing.

I sure wouldn't mind somebody letting me have a -6 so I can verify exhaust clearances to the "cable" set-up. Of course, I'd need the 915 trans to mount it in place.

Wes

Wilhelm

Oct 6 2008, 08:25 PM

QUOTE(andys @ Oct 6 2008, 08:57 AM)

QUOTE(PRS914-6 @ Oct 5 2008, 07:50 AM)

Another thought on your idea........I don't have an arm here to look at but is there enough room to cut the arm (notch it) and weld a tube in its place with a straight shot to the mechanism? Also, I'm not sure but I'll look the next time my car is on the rack but there might be header interference with the cable out away from the arm...it's very close on a 6. Might need a tight 90 deg there.

You can draw a sketch of exactly what you want and send it to Terry cable and they will manufacture the cable perfectly as you like.

Wes,

Very nice write-up!

For you bell crank types, Wes came up with a very clever solution which employs a compound bell crank that provides opposing actions. He claims it's a bit too complex but, I disagree and think it's a unique solution and it allows the use of the stock e-brake cables. Wes, can you post some photos of this?

The one funamental problem with the 911 e-brake is getting a nice straight shot at the actuator. All the solutions place the cable at a slight angle; I don't know for sure how much of a real issue this is (perhaps none) but it "seems" less than ideal. Short of modifying the trailing arm, you're pretty much stuck with this as is.

Wilhelm, do you have a close photo of that 928 brake shoe spreader? Seems like it would simplify things quite a bit.Andys

Here they are:

All the parts seperated

Click to view attachmentCable attached

Click to view attachmentHooked to spreader

Click to view attachmentIn the un-expanded mode

Click to view attachmentAgain in the unexpanded mode attached to shoes

Click to view attachmentIn the expanded mode attached to shoes (Note: the shoes are now farther apart)

Click to view attachmentThe end for the parking brake cables for this application can be found here:

http://www.aircraftspruce.com/catalog/appages/ms20667.phpThis is what I'll be using with my trailing arms from another thread:

http://www.914world.com/bbs2/index.php?showtopic=86910

ClayPerrine

Oct 6 2008, 09:53 PM

I actually looked at the 924/944 solution. The mount for the cable is integral with the backing plate, and to use that backing plate would require way more modification than I am willing to do. Plus it puts the calipers behind the trailing arms, and they then hit the shock mount bolt.

The 944 shoes will fit the 911 backing plates. If someone made a mount to hold the expander and the end of the cable, it would work.

But you are still left with custom cables.

Wilhelm

Oct 6 2008, 10:37 PM

QUOTE(ClayPerrine @ Oct 6 2008, 07:53 PM)

I actually looked at the 924/944 solution. The mount for the cable is integral with the backing plate, and to use that backing plate would require way more modification than I am willing to do. Plus it puts the calipers behind the trailing arms, and they then hit the shock mount bolt.

The 944 shoes will fit the 911 backing plates. If someone made a mount to hold the expander and the end of the cable, it would work.

But you are still left with custom cables.

Easy deal is to use the stock 914 cable terminating where it normally does. Pull the inner cable out and put in a bus cable (longer) . Now run this cable back to a small pulley (sheeve for you mariners) to change direction right in back of the pull point for the 944/928 spreader which should be a 6 oclock when using the 911 backing plate. Crimp one of these suckers on to the end of the cable

http://www.aircraftspruce.com/catalog/appages/ms20667.php. The most challenging fab would be welding a bolt on for the pulley. I'll post a pict when I'm done.

ClayPerrine

Oct 7 2008, 07:42 AM

QUOTE(Wilhelm @ Oct 6 2008, 11:37 PM)

QUOTE(ClayPerrine @ Oct 6 2008, 07:53 PM)

I actually looked at the 924/944 solution. The mount for the cable is integral with the backing plate, and to use that backing plate would require way more modification than I am willing to do. Plus it puts the calipers behind the trailing arms, and they then hit the shock mount bolt.

The 944 shoes will fit the 911 backing plates. If someone made a mount to hold the expander and the end of the cable, it would work.

But you are still left with custom cables.

Easy deal is to use the stock 914 cable terminating where it normally does. Pull the inner cable out and put in a bus cable (longer) . Now run this cable back to a small pulley (sheeve for you mariners) to change direction right in back of the pull point for the 944/928 spreader which should be a 6 oclock when using the 911 backing plate. Crimp one of these suckers on to the end of the cable

http://www.aircraftspruce.com/catalog/appages/ms20667.php. The most challenging fab would be welding a bolt on for the pulley. I'll post a pict when I'm done.

The spreader mechanism on a 944 mounts to the backing plate. The 944 backing plate will not fit a 914 trailing arm.

Where are you going to mount the spreader?

Wes V

Oct 7 2008, 11:03 AM

(I'm glad I started this sting)

Here's a bunch of thoughts and questions on the 944 spreader method (the "wilhelm" method).

In the stock configuration, does the spreader assembly just float free, held in compression by the shoes?

Looking back at the factory diagram posted by Wilhelm, what is item 23? What function does it serve?

When Clay says that the backing plate supports the cable, to be specific, is he taking about the "dead-head" anchoring of the sheathing. I'm pretty sure this is what he is saying due to sheathing having to be fixed in order for this to work. This is significant due to the fact that it wouldn't be required if a bell-crank was used (as in some of the other methods.

You couldn't use the VW bus cable due to it's end not being compatable. There just isn't any reason for it, other than being longer.

I have to assume that there is somthing like the 40mm spacer at the spreader, as there is on the 911, welded to the trailing arm.

Here is how I view it being done (if possible);

Use the early 911 backing plate and cut out the minimum to allow the 944 spreader to fit. Mount the shoes and spreader.

Fab up and weld in place the equivalent bracket as the 40mm one used in 911 installations. A hole would be needed for clearance for the "pull rod".

Use a bell-crank as shown in prior posts.

Connect the bell-crank to the spreader with a threaded rod and clevis. (NOT CABLE)

Remove and relocate (weld) the bracket that holds the stock 914 cable, directing it toward the bell-crank.

Attach the end of the stock 914 cable to the bell-crank using an "extension" arm as shown in prior posts, if required.

If all this works, I really like the solution. The fabrication work isn't that complicated and it would provide the most clearance from things like the exhaust piping.

I really wish that there was a 944 around here that I could take the rotors off and check it out, take measurements, and such.

Wes

Wes V

Oct 7 2008, 11:51 AM

I think it dawned on me why Clay said that the 944 spreader is "attached" to the backing plate.

I think it's that the backing plate prevents the spreader from being pulled outward by the cable.

The green line would be the backing plate.

The spreader would "wipe" across the backing plate a small amount.

It may also help answer that that item 23 is.

If this isn't the case, then function wise, it's doing pretty much what the "single spreader / pull only" method does. It would dig the brake shoes into the backing plate with the force applied by the pull cable.

Fab'ing up this bearing plate in the correct location would be difficult (at least for me) and may be why Clay ruled it out.

Wes

jcd914

Oct 7 2008, 12:56 PM

QUOTE(Wes V @ Oct 7 2008, 10:51 AM)

I think it dawned on me why Clay said that the 944 spreader is "attached" to the backing plate.

I think it's that the backing plate prevents the spreader from being pulled outward by the cable.

I think you are correct here.

Although I have not looked at the rear brakes of a 944 in a long time I think the spreader actually rests/is pulled against the backing plate nearer the ends of the spreader. The curved ends provide a pivot that is stable and would not move around much and have good leverage.

The green lines here would be the backing plate.

Click to view attachmentThe opening in the backing plate for the cable would also have top be big enough to allow the nub on the spreader to clear.

I do like the idea of using the 944 spreader with the bell crank method already used by some.

Anyone know if real early 911 (66-68 with short wheelbase) rear parking brakes are any different than the rest? I have what I believe to be a set of 911 short rear trailing arms with brakes in my spare parts.

Great thread

Jim

ClayPerrine

Oct 7 2008, 01:26 PM

66-68 911 park brakes are the same as the later ones. The later ones just use a different center section on the backing plate for the different bearing.

Wes V

Oct 7 2008, 07:09 PM

I formally bow in humility to Clay Perrine!

I had the local Porsche dealer pull up the PET diagram that shows the 1981 924 backing plate and I can see that modifying the 911 backing plate to work in the same fashion would be difficult and I don't think it would be worth it!!

The backing plate not only has the equivalent of the 40mm shoe support, but also the two bearing pads for the separator tabs (as shown by jcd914's diagram).

All of that could be addressed, but the little details just keep adding up to the point where it's not worth it.

(in my defence, I think it's always good to go in and "re-think" stuff that may be considered as fact)

Wes Vann

craig downs

Oct 7 2008, 11:55 PM

I've been working on this also for about two weeks. Knowing that other cars use this type of e-brake arrangement I went to Pick-a Part to look at some cars. Almost all European cars use this type of spreader.

The spreader didn't appear to be supported in the rear but relied on the notches in the shoes and spring tension from the shoes. The whole thing fit in a pocket in the backing plate that was part of the trailing arm. But one could and would be a good idea to put some support for it in the 40mm shoe anchor.

craig downs

Oct 8 2008, 12:05 AM

Here a little what I've done

You have to remove a section of the backing plate to make room for the spreader

Click to view attachmentClick to view attachment

craig downs

Oct 8 2008, 12:07 AM

craig downs

Oct 8 2008, 12:28 AM

911 shoe on the left and a 944 on the right it the same shoe except the 944 has a notch for the spreaders instead of the pins for the 911. Also the 944 has a slot instead of a hole for the retainer spring that holds it to the backing plate.

The spreader on the left is out of a BMW which the cable pulls 90 degrees to the backing plate. The spreader on the right is from a 924/944 and the cable comes in at an angle to the backing plate.

The tangs on the back of the BMW spreader is so the loose pin that hooks the cable to the spreader doesn't fall out.

Click to view attachment

smdubovsky

Oct 8 2008, 09:39 AM

Just about every porsche other than the 911/912 & 914 uses the same newer lever design and same brake shoes 930/964/993/996/986/997/924/944/928.

Hmmm, I have some E30 parts laying around somewhere taken off the racecars. I should compare. FWIW, the E30 has a bolt on support (part #3). If its the same width as the stop plate you have to weld on anyway it could kill 2 birds w/ one stone.

Craig downs is correct. The reason for the ears is to keep the pin from falling out when you pull on the cable.

Click to view attachmenthttp://www.realoem.com/bmw/showparts.do?mo...hg=34&fg=30

andys

Oct 8 2008, 11:12 AM

Guys,

Keep up the good work. This thread is getting real interesting and informative.

Andys

Richard Casto

Oct 8 2008, 02:51 PM

Just spent a few minutes looking at PET for 924, 944 and 928 (can't get the 924S PET to download right now)

* The pad spacer is part of the 911 rear suspension arm and not the backing plate. (already knew this)

* The 76-79 924, 82-85 944 and all years of the 928 have a backing plate but the pad spacer is part of the backing plate. Hard to tell, but plate looks thicker than 911 plate.

* The 88+ 944 did not have a backing plate (or pad spacer), but rather it is part of suspension arm.

* All 928 use the same spreader (993 352 073 00) which looks to be a 90 degree pull

* All 924/944 use the same spreader (951 352 090 00) which looks to be a side pull

My take away from this is ...

* The 911 backing plate it too thin to handle loads when the e-brake is engaged. (some people weld the spacer to 911 backing plate, some weld it to the 914 rear suspension arm)

* Backing plates for the 924 and 928 were made thicker so they can incorporate the pad spacer and can cary the braking load??

* Some later cars did away with the backing plate and incorporated it into the rear axle casting.

* Backing plates between models look to be significantly different. Not sure how much if any swapping can happen.

* Would the 924/944 spreader work better as it is a side pull and that might line up better with the stock 914 e-brake setup since if I remember correctly the rear 914 e-brake is a side pull and not a 90 degree pull? Could this mean no need for a bellcrank if you use the 924/944 spreader, but just a short custom cable to bridge between the spreader and the stock 914 cable?

Richard Casto

Oct 8 2008, 02:55 PM

Craig,

Excellent job! It looks like you are well on the way of figuring this out!

I assume the next step in the photo below is to weld in a spacer for the pad and that same spacer might do the same job as the 924/944/928 backing plate and act as a brace for the spreader? After you run cables, it looks like you might have a working solution using the pull spreader!

Richard

QUOTE(craig downs @ Oct 8 2008, 02:07 AM)

Richard Casto

Oct 8 2008, 03:08 PM

QUOTE(craig downs @ Oct 8 2008, 02:28 AM)

911 shoe on the left and a 944 on the right it the same shoe except the 944 has a notch for the spreaders instead of the pins for the 911. Also the 944 has a slot instead of a hole for the retainer spring that holds it to the backing plate.

The spreader on the left is out of a BMW which the cable pulls 90 degrees to the backing plate. The spreader on the right is from a 924/944 and the cable comes in at an angle to the backing plate.

The tangs on the back of the BMW spreader is so the loose pin that hooks the cable to the spreader doesn't fall out.

Click to view attachmentQuestions and comments...

It looks like you are using a 911 backing plate. With the 944 shoe having a slot vs. a hole for the retainer spring does that mean you have to use the 911 shoe? If you are using the 911 shoe, are you grinding a notch for the spreader?

Also, you mention that the 90 degree spreader is from a BMW. If you look at the PET diagram for the 928, the BMW and 928 spreader look the same if not identical.

ClayPerrine

Oct 8 2008, 03:09 PM

I have had sitting side by side in front of me a 944 backing plate and a 911 backing plate.

You have all seen the 911 backing plate.

the 944 backing plate is a cast aluminum part that incorporates both the shoe stop and the caliper mounting point, plus the bearing cap. The center of the cast aluminum part won't fit over the 914 trailing arm, it is too small. And he offset for the shoes and the caliper mount is completely wrong to work with the 914 trailing arm, even if it would fit. Plus, the caliper mount is on the back of the trailing arm on a 944, so to use it on a 914, the cable would have to come from the rear.

I like the idea of using 944 shoes and the spreader, but I will be much harder to do than the 911 setup. If someone made a custom backing plate with a cable pull from the front in parallel with the trailing arm it would be a slick item.

(DAMN... now I am thinking again!!!!)

BTW.. my park brake works fine. I drove it to work this morning.

craig downs

Oct 8 2008, 09:04 PM

I'm totally aware of how the backing plate is on a 944 and I'm not using or trying to use it I'm using a 911 backing plate. I don't understand what difference which backing plate you use. When I was looking into this idea if it would work I checked the shoe size, position, and the gap between the shoes where the spreader goes to see if they were the same as the 911 and they were. The only difference in the shoes are the pins for the 911 spreaders and the holes for the retaining springs that holds them to the backing plate. The 911 has a hole and the 924/944 has a slot.

If you want to use the 911 shoes you have to remove the pins and grind a notch for the spreaders. If you want to use the 924/944 shoes all you have to do is to drill a hole where the slots are for the spring retainers.

The shoe anchor will have rear support for the spreaders and be welded to the trailing arms.

I know your a big fan of cables which is fine. Just looking at another alternative

Wes V

Oct 9 2008, 09:31 AM

Craig;

On the prior page, jcd914 posted a photo showing in green lines where the spreader would bear on the backing plate.

The PET backing plate diagram I've seen has the spreader sitting on a raised area.

In all disk brake installations, the shoes sit on raised sections. This is true on 911 backing plates and also on 924 backing plates.

Now the question I've got (and hopefully you have a 924 backing plate you can look at) is if the raised pad supporting the spreader is at the same elevation as the pads that the shoes rest against.

Wes V

This is a "lo-fi" version of our main content. To view the full version with more information, formatting and images, please

click here.