1. Inside the bore of the caliper there is a pin that goes into a mechanism within the piston. What the heck is it for? How do I remove it? Is it screwed into the caliper body or just press fitted into place. It needs to be removed in order to hone the bore.

2. If I can get rid of the "pin" within the bore of the caliper, what pistons can I use. I know it's easy to remove the mechanism within the piston (simple snap ring), but I have to get new pistons anyway. An actual porsche part number would be nice!! (Stoddard lists some aftermarket 38mm stainless steel pistons, but I'm not sure if they are applicable or have the stepped to surface talked about in the next point)

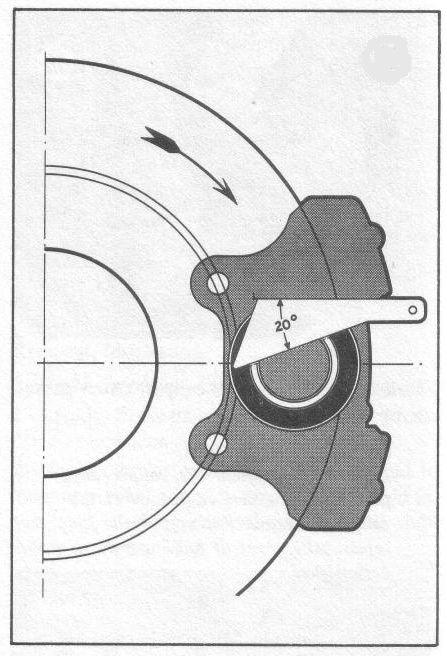

3. The pistons have to be installed (rotated) as shown in the following diagram.

This places the lower "stepped" surface of the piston in the upper position.

It's not due to the pad having an "index'd" matching surface (the pad just has a flat surface), and as such I've got to ask why it matters? (I have to assume it's so that the initial "bite" of the pad is lessened on the leading edge)

4. Are any of the "rebuild" kits better than others. (the kit normally is just the piston o-ring, dust seal, and retainer clip) Are there any to avoid?

5. The four bolts that hold the calipers together are 7mm (from the factory) and when loose, the parts of the caliper sure sure do flop around a lot!! Has anybody used 8mm bolts to help alignment and also be stronger. Where would you get 8mm bolts in the correct grade (12.9?). If you just use the factory 7mm bolts, are there any secrets to keeping everything aligned while tightening. (since I'm talking about the bolts, what should they be torqued too?) Other than the factory, is there a good source for the bolts?

6. Any idea on cost of zinc plating? (the parts have been blasted and clean)

Wes Vann